408-8959

Rev C

4

of 6

Visual Inspection

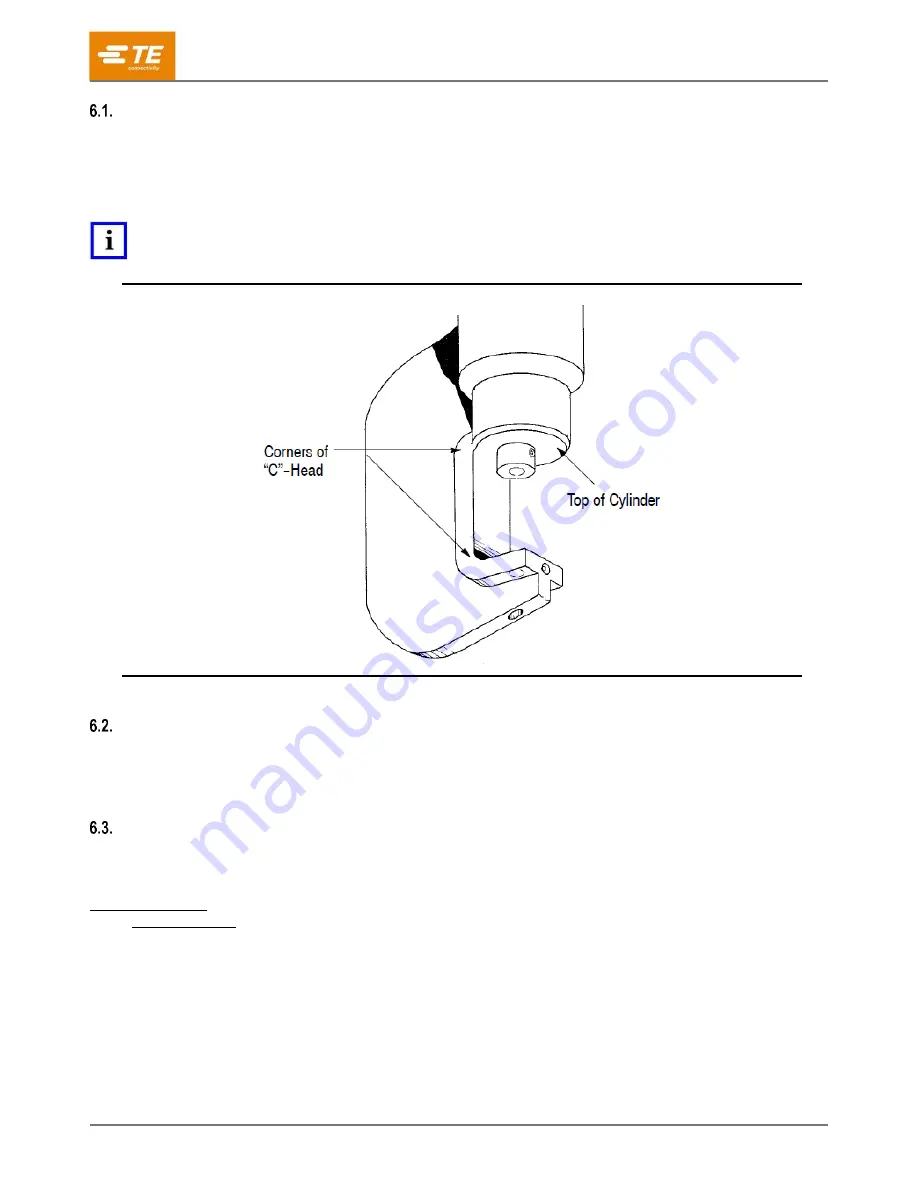

Refer to Figures 3 and 5; proceed as follows:

1. Inspect the assembled crimping head for nicks, scratches, cracks, and excessive wear, especially

where sliding contact occurs.

2. Inspect for cracks particularly at the corners of the

“

C

”

-Head and around the top of the cylinder.

NOTE

Once per year, or every 7,500 cycles (whichever comes first), the hydraulic head should be returned to TE for magnetic

particle inspection. Additionally, inspect and service the head every month or 1,000 cycles.

Figure 3

Cleaning

1. Remove accumulations of dirt and grease on the crimping head; especially in areas where dies are

installed and product is crimped.

2. Clean the entire head frequently with a clean, lint-free cloth.

Crimping Head Check-Out Procedure

If the ram fails to retract after completion of a crimping cycle, the cause may be in the crimping head. To

determine whether the trouble is in the crimping head or not, release pressure in the power unit.

If the ram retracts, the trouble is not in the crimping head.

If ram does not retract, refer to paragraph 7. REPLACEMENT and REPAIR