NOTE

i

408-1610

8 of 11

Rev M

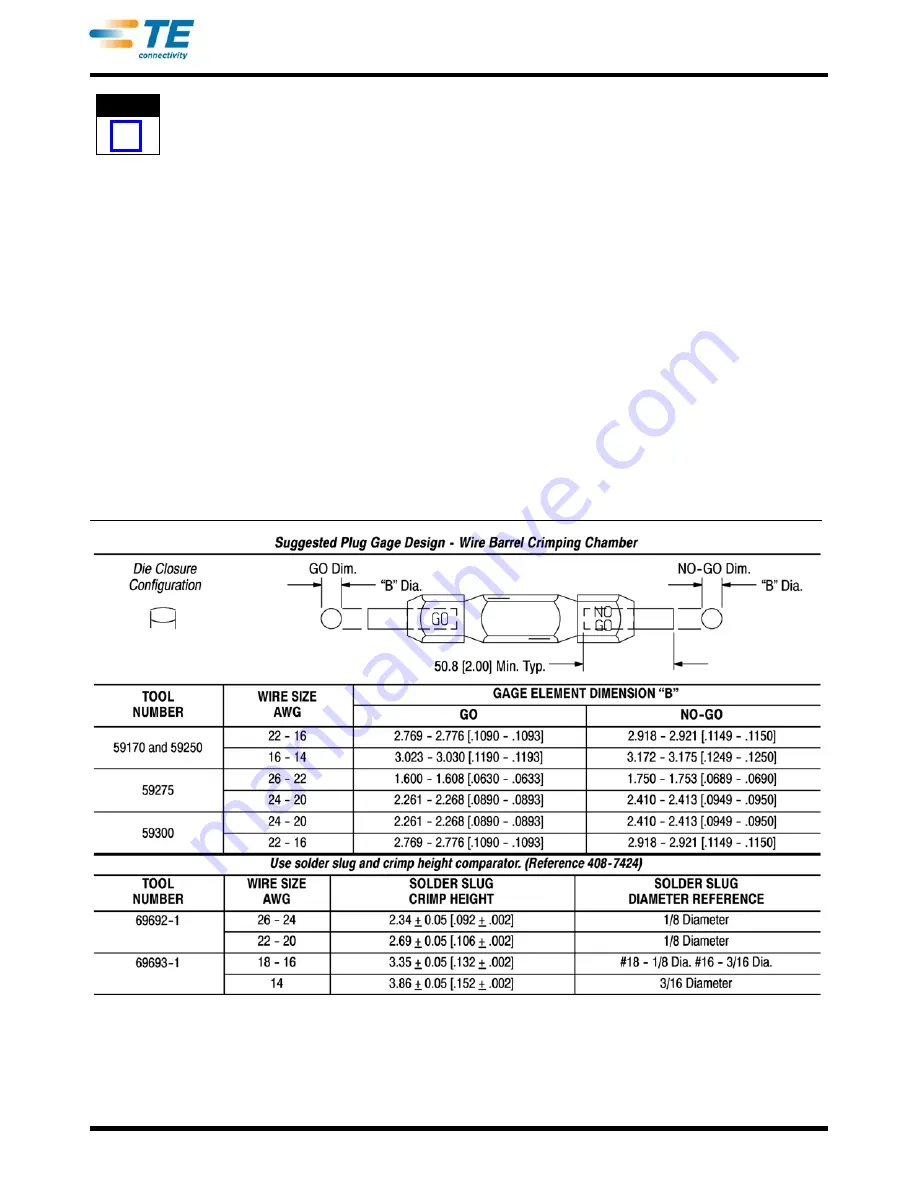

Refer to the table in Figure 11 for alternate hard

gage dimensions for tools 69692-1 and 69693-1.

A. Gaging the Crimping Chamber Using A Plug Gage

This inspection requires the use of plug gages

conforming to the dimensions listed in Figure 9 and

Figure 10. Tyco Electronics does not manufacture or

market these gages. Refer to 408-7424 for information

concerning plug gages

To gage the crimping area(s), refer to Figure 12 and

proceed as follows:

1. Clean oil or dirt from the crimping chamber and

plug gage.

2. Close handles of tool until wire barrel dies are

bottomed. Do not apply additional pressure to tool

handles.

3. With wire barrel dies bottomed, inspect the wire

barrel crimping chamber using the proper plug

gage. Lift the spring-loaded locator up and hold

gage in straight alignment with the crimping

chamber. Carefully try to insert, without forcing, the

GO element. See Figure 12, Detail A. The GO

element must pass completely through the crimping

area.

4. Try to insert the NO-GO element. The NO-GO

element may enter partially, but must not pass

completely through the crimping area.

5. Set insulation adjustment indicator in Position 1.

Measure both insulation crimping chambers with the

proper GO plug gages in the same manner as Steps

2 and 3. See Figure 12, Detail B.

6. Set insulation adjustment indicator in Position 4.

Measure both insulation crimping chambers with the

proper NO-GO plug gages in the same manner as

Steps 2 and 4. See Figure 12, Detail B.

If the crimping areas conform to the gage inspection,

the tool is considered dimensionally correct. If the

crimping areas do not conform to the inspection, the

tool must be repaired. Refer to Section 8,

REPLACEMENT AND REPAIR.

Figure 9