408-1536

Rev J1

2

of 7

CRIMPING PROCEDURE

NOTE

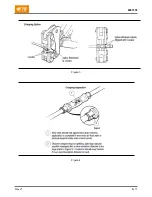

Each hand tool is coated with a preservative to prevent rust or corrosion. Wipe this preservative from

the tool, particularly from the dies, before using the tool.

1. Select the correct splice for the wire size and wire insulation diameter being used. Observe color

coding of splice, rings, adaptors, and tools (see Figure 2).

Wire

Splice

Splice

Wire Strip

Length

mm [inch]

Splice Body

and Tool

Color Code

Tool

Adapter

Ring Color

Size Range

(AWG)

Max Insul

Diameter

mm [inch]

A

B

C

D

24-20

1.65 [.065]

324987

Yes Yes

Green

Green

7.37 [.290]

Tin

(White)

46073

1.85 [.073] 1-324987-0

Orange Orange

1.85 [.073]

1-324987-1

---

Yes

---

Orange

2.54 [.100]

---

---

Tin

---

6.35 [.250]

2.54 [.100]

324544

---

Tin

20-18

2.57 [.101]

324988

Yes Yes Green

Green 7.87 [.310]

Red

46074

3.38 [.133]

324548

---

---

Tin

Tin

7.11 [.280]

Figure 2

2. Strip the wire to dimensions listed in Figure 2.

DO NOT

nick or cut the wire strands.

3. Open the dies by squeezing the tool handles together until the ratchet releases.

4. Select the proper color-coded end of splice (when applicable) for the wire insulation diameter being

used (see Figure 2).

5. Insert stripped wire into splice until it bottoms against wire stop. End of conductor should be visible

through transparent window indent of splice.

6. Align splice window indents with tool locator, and push splice into locator until splice bottoms (see

Figure 3).

7. Hold wire in place and squeeze tool handles together until the CERTI-CRIMP ratchet releases. Allow

tool handles to open FULLY. Crimped splice may be removed.

8. To crimp other half of splice, position uncrimped half in tool and follow same procedure used to crimp

first half of splice. If splice cannot be turned, turn tool around.

9. Refer to Figure 4 for splice crimp inspection.