5

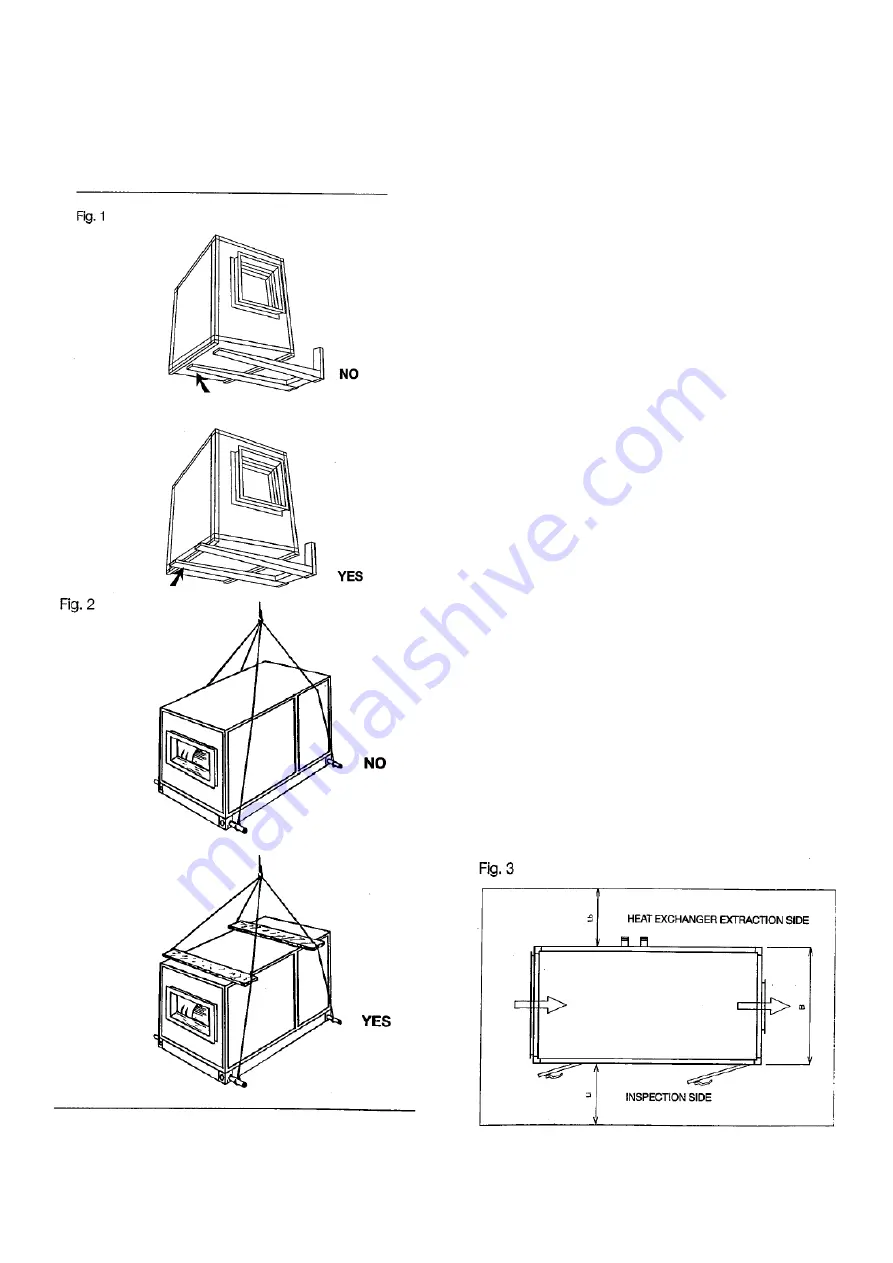

If a crane is used, proceed as shown in the illustration,

using spacers to protect the structure (fig. 2).

- During transportation, protect the unit from

atmospheric agents. Special care must be taken if the

unit is supplied disassembled or designed for internal

use.

3.

ASSEMBLY ON SITE

3.1.

POST-TRANSPORTATION CHECK

When the Air Treatment Unit arrives on site, we

recommend you to make a careful inspection of the

structure and the component parts of the unit.

Should you come across damage sustained during

transportation, you must report it on the freight bill. The

carrier must immediately tile a report of the accident to

obtain compensation from the insurance company

3.2. PRESERVATION ON SITE

In order to keep the Air Treatment Unit in good and

efficient condition on site, the following steps must be

taken first:

- Prior to installation, position the Unit and the

accessories in a place affording the best possible

protection against accidental knocks, dust and

atmospheric agents

- Carefully cover the inlets and outlets to prevent foreign

matter from entering the unit and damaging the internal

components

- Extract the pre-filters from the Unit and put them in a

protected place to preserve their filtration efficiency

This is why the superior efficiency filters are delivered

packed; they must be kept in their packages until the

unit is put into service

- Check that the hydraulic connections are protected by

the relevant caps as they were on delivery to the TCF

plant. lf they are not, plug them in order to protect the

exchangers.

3.3.

POSITIONING

3.3.1. Dimensions of installation room

The Air Treatment Unit installation room must be of

sufficient size to permit easy inspection, maintenance

and component replacement.

Accordingly,

the

following

dimensions

are

recommended [fig. 3):