USER INTERFACE

5-3

Model C707

User Interface

5

To resume normal operation, press the AUTO key. When

the machine cycles off, the product in the freezing

cylinder will be at serving viscosity. At this time, place the

feed tube

(end with the hole)

into the mix inlet hole and

install the air orifice.

Figure 5-3

WASH Key

When the WASH key is pressed, the light comes on. This

indicates beater motor operation. The STANDBY or

AUTO modes must be canceled first to activate the

WASH mode.

AUTO Key

When the AUTO key is pressed, the light comes on. This

indicates that the main refrigeration system has been

activated. In the AUTO mode, the WASH and STANDBY

functions are automatically canceled. The MIX REF

function is automatically locked in to maintain the mix in

the mix hopper.

Note:

An indicating light and an audible tone will sound

whenever a mode of operation has been pressed. To

cancel any function, press the key again. The light and

mode of operation will shut off.

Beater Motor RESET Button

The RESET button is located on the left side of the

machine. The reset protects the beater motor from an

overload condition. If an overload occurs, the reset

mechanism will trip. To properly reset the freezer, press

the AUTO key to cancel the cycle. Turn the power switch

to the OFF position. Press the RESET button firmly.

DANGER! DO NOT

use metal objects to press

the RESET button. Failure to comply may result in severe

personal injury or death.

Turn the power switch to the On position. Press the

WASH key and observe the freezer’s performance. Open

the side access panel. Make sure the beater motor is

turning the driveshaft in a clockwise direction (from the

operator end) without binding.

If the beater motor is turning properly, press the WASH

key to cancel the cycle. Press the AUTO key to resume

normal operation. If the freezer shuts down again,

contact a Taylor service technician.

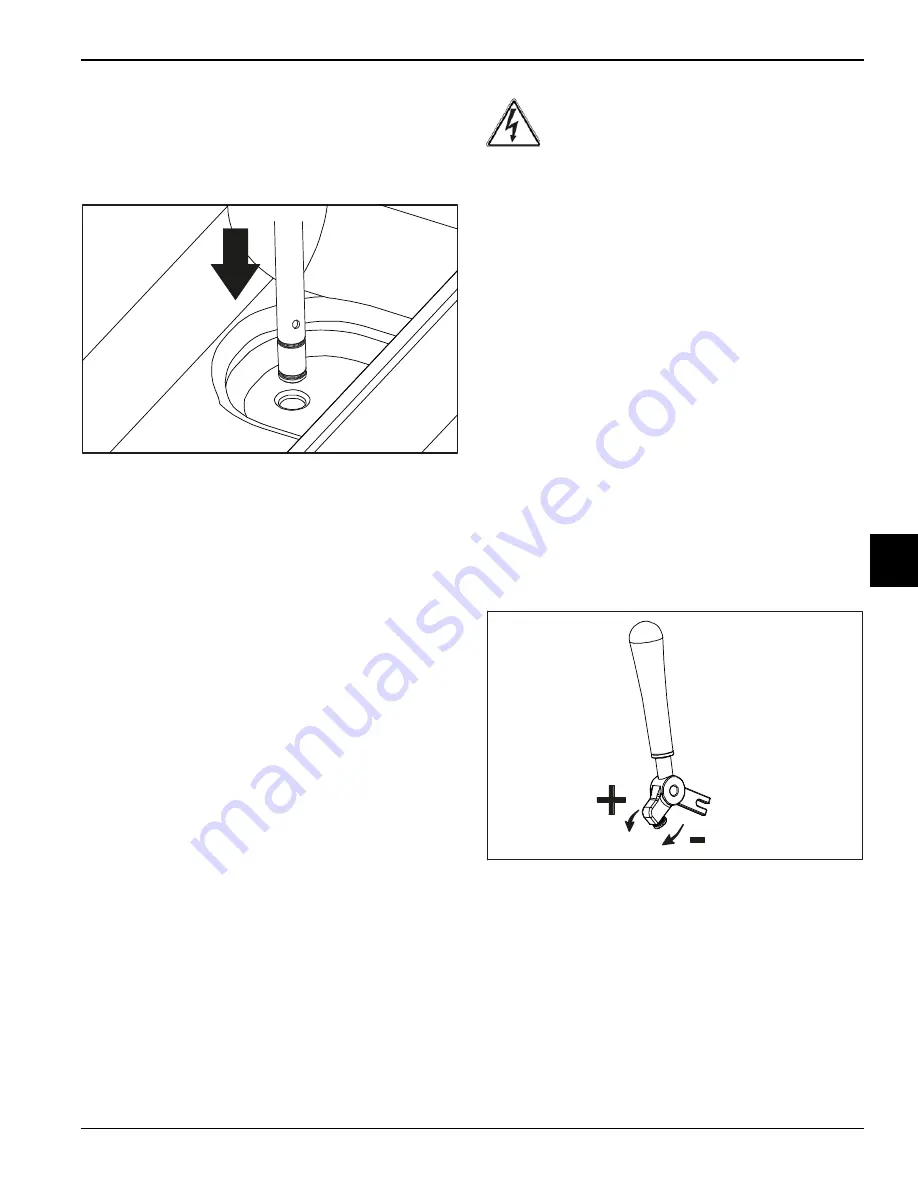

Adjustable Draw Handle

The Model C707 features an adjustable draw handle to

provide the best portion control. The draw handle should

be adjusted to provide a flow rate of 5 oz. to 7-1/2 oz.

(148 ml to 222 ml) of product per 10 seconds. Turn the

screw

clockwise

to

increase

the flow rate. Turn the

screw

counterclockwise

to

decrease

the flow rate.

Figure 5-4

12304

10354

Summary of Contents for C707

Page 16: ...4 4 OPERATOR PARTS IDENTIFICATION Model C707 Operator Parts Identification 4 Notes ...

Page 36: ...9 2 PARTS REPLACEMENT SCHEDULE Model C707 Parts Replacement Schedule 9 Notes ...

Page 40: ...10 4 LIMITED WARRANTY ON MACHINES Model C707 Limited Warranty on Machines 10 Notes ...

Page 44: ...11 4 LIMITED WARRANTY ON PARTS Models C707 Limited Warranty on Parts 11 Notes ...