8

Models 369/370/371

5 - Remove the bowl gasket from its seat (see figure 11).

figure 11

6 - Dismantle the faucet assembly (see figure 12).

figure 12

7 - Slide the drip tray out and empty it.

5. 3. 2 CLEANING

1 - Prepare at least two gallons of a mild cleaning solution of

wa rm (45-60 °C / 12 0-140 °F) potable wa ter and

dishwashing detergent. Do not use abrasive detergent.

Important: if present, follow label directions, as too strong

a solution can cause parts damage, while too mild a

solution will not provide adequate cleaning.

2 - Using a brush suitable for the purpose, thoroughly clean all

disassembled parts in the cleaning solution.

3 - Do not immerse the lighted top covers in liquid. Wash them

separately with cleaning solution. Carefully clean the

bottoms of the covers.

4 - In the same manner, clean the evaporator cylinder(s)

using a soft bristle brush.

5 - Rinse all cleaned parts with cool, clean water.

5. 3. 3 SANITIZING

Sanitizing should be performed immediately prior to starting

the machine. Do not allow the unit to sit for extended periods of

time after sanitization.

1 - Wash hands with a suitable antibacterial soap.

2 - Prepare at least two gallons of a warm (45-60 °C / 120-

140 °F) sanitizing solution (100 PPM available chlorine

concentration or 1 spoon of sodium hypoclorite diluted with

half a gallon of water) according to your local Health

Codes and manufacturer’s specifications.

3 - Place the parts in the sanitizing solution for five minutes.

4 - Do not immerse the lighted top covers in liquid. Carefully

wash their undersides with the sanitizing solution.

5 - Place the sanitized parts on a clean dry surface to air dry.

6 - Wipe clean all exterior surfaces of the unit. Do not use

abrasive cleaner.

5. 3. 4 ASSEMBLY

1 - Slide the drip tray into place.

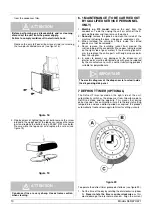

2 - Lubricate faucet piston, inside auger and outer spiral (see

points A, B and C of figure 13) only with the grease

supplied by the manufacturer or other

food grade

approved

lubricant.

figure 13

3 - Assemble the faucet by reversing the disassembly steps

ATTENTION

Before any disassembly and/or cleaning procedure

disconnect the unit from the power supply.

Failure to comply could result in electrical shock.

IMPORTANT

Do not attempt to wash any machine components in a

dishwasher.

IMPORTANT

Prior to any cleaning or sanitizing procedure hands

washing is required.

IMPORTANT

In order to prevent any damages to the dispenser, use

only a detergent suitable for plastics parts.

ATTENTION

When cleaning the machine, do not allow excessive

amounts of water around the electrically operated

components of the unit. Electrical shock or damage to

the machine may result.