Models 369/370/371

5

ENGLISH

4 TO OPERATE SAFELY

1 -

Do not

operate the dispenser without reading this

operator’s manual.

2 -

Do not

operate the dispenser unless it is properly

grounded.

3 -

Do not

use extension cords to connect the dispenser.

4 -

Do not

operate the dispenser unless all panels are

restrained with screws.

5 -

Do not

obstruct air intake and discharge openings: 15 cm

(6”) minimum air space around all sides of the dispenser.

6 -

Do not

put objects or fingers in panels louvers and faucet

outlet.

7 -

Do not

remove bowls, augers and panels for cleaning or

routine maintenance unless the dispenser is disconnected

from its power source.

5 OPERATING PROCEDURES

1 - Clean and sanitize the unit according to the instructions in

t h i s m a n u a l . S e e c h a p t e r 5 . 3 C L E A N I N G A N D

SANITIZING PROCEDURES.

2 - Fill the bowls with product to the maximum level mark. Do

not overfill.

The exact quantity of product (expressed as liters and

gallons) is shown by marks on the bowl.

3 - In case of products to be diluted with water, pour water into

bowl first, then add correct quantity of product. It is

advisable to strain the natural fruits to prevent pulps from

obstructing the faucet outlet.

4 - To obtain the best performance and result, use bases

designed to be run in Granita freezers.

If natural juices (e.g. lemon, orange) as well as sugarless

products (e.g. coffee) are used, dissolve 150 - 200 grams

of sugar per liter.

5 - For soft drink use the unit doesn’t need any minimun brix

level.

6 - Install the covers and check that they are correctly placed

over the bowls. The dispenser must always run with the

covers installed to prevent possible contamination of the

product.

7

- Set the control switches as shown in chapter

5.1 DESCRIPTION OF CONTROLS.

8 - Always leave the dispenser on, as the refrigeration stops

automatically when Granita reaches the proper thickness.

The mixers will continue to turn.

5. 1 DESCRIPTION OF CONTROLS

The dispenser is equipped with a power switch and a light

switch. In addition each bowl is individually operated by a

mixer/refrigeration switch. In fact it is possible to dispense both

soft drinks and Granita.

When a bowl is in Soft Drink mode, the beverage temperature

is controlled by the corresponding thermostat.

When a bowl is in Granita mode, the mix viscosity is controlled

by the corresponding adjustment screw located in the rear wall

of each container (for temperature and viscosity setting refer to

chapter 5.2 OPERATION HELPFUL HINTS).

All the switches are located on the faucet side of the dispenser

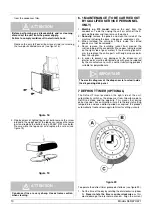

behind switch covers (see figure 2).

figure 2

In addition all the models except 369 are equipped with an

automatic safety pressure switch to prevent damages to the

compressor. The lighting of the light at the left of the switch

covers indicates insufficient ventilation of the unit. If this occurs

check that there is sufficient space on all sides for ventilation

(at least 15 cm (6”) on each side) and that condenser filter is

free from dust or other obstructions.

In case the warning light is still ON after these operations have

been carried out a service call is required.

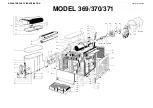

Dispenser controls functions are as follows (see figure 3):

figure 3

Power switch (A)

Light switch (E)

Mixer/refrigeration switch (B)

Thermostat (D)

IMPORTANT

Brix (sugar percent content) must be at least 13 for all

granita products.

IMPORTANT

Operate the dispenser with food products only.

0 position

:

power is turned OFF to all functions.

I position

:

power is turned ON to all functions

and the other switches are enabled.

The fan motor runs.

0 position

:

all top cover lights are OFF.

I position

:

all top cover lights are ON, provided

that power switch (A) is set to I.

I position

:

mixer and refrigeration ON.

SOFT DRINK mode.

0 position

:

OFF.

II position

:

mixer and refrigeration ON.

GRANITA mode.

Turn clockwise

: to decrease temperature

Turn counterclockwise

: to increase temperature