•

When working with wood that has been

processed before, watch out for foreign bodies

such as nails or screws etc.

•

Before you actuate the On/Off switch, make

sure that the saw blade is correctly fitted and

that the machine’s moving parts run smoothly.

•

Use clamps or a vise to hold the workpiece

securely. This is safer than using your hand.

•

Follow the instructions for lubrication and

changing tools.

•

Keep handles dry, clean and free from oil and

grease.

•

Keep the push stick or handle for a push block

at the machine at all times, even when you are

not using them.

•

Do not cut rebates or grooves without fitting a

suitable guard, e.g. a tunnel-type guard, over

the saw table.

•

Use only the transport device for transporting

the machine.

•

While you are moving the machine it is best to

cover the top part of the blade, for example

using a guard.

Do not misplace these safety instructions.

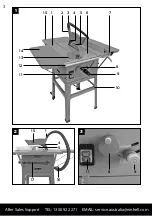

2. Layout

1.

Saw bench

2. Saw blade guard

3. Extractor hose

4. Splitter

5. Saw blade

6. Table insert

7. Parallel stop

8. Hand crank

9. Adjustment and locking grip

10. Base frame

11.

ON/OFF switch

12. Chain bar for parallel stop

13. Cross stop

14. Width extension table

15. Length extension table

16. Extractor adapter

17. Push stick

18. Legs

19. Longitudinal and cross-struts

20. Middle struts

21. Rubber feet

22. Stability bar

23. Table supports

24. Screw with wing nut

25. Oval holes

26. Countersunk screws

27. Fixing screw

28. Eccentric lever

29. Groove

30. Knurled screw

31. Laser

32.

ON/OFF Switch for laser

33. Screws for battery compartment

34. Battery compartment cover

17

After Sales Support TEL: 1300 922 271 EMAIL: [email protected]

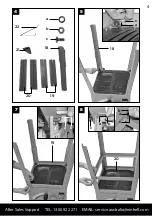

3. Items supplied

•

Operating Instructions

•

2 x Battery 1.5V LR 03

•

Base frame

•

Bench circular saw

•

2 x Carbide metal covered saw blades (1 x 24

•

teeth, 1 x 48 teeth)

•

Parallel stop

•

Cross stop

•

Push stick

4. Proper use

The bench-type circular saw is designed for the

slitting and cross-cutting (only with the cross

stop) of all types of timber, commensurate with

the machine’s size. The machine is not to be

used for cutting any type of round wood.

The equipment may only be used for the tasks it

is designed to handle. Any other use is deemed

to be a case of misuse. The user/operator - not

the manufacturer - will be liable for any damage

or injuries caused as a result thereof.

Please note that our equipment has not been

designed for use in commercial, trade or

industrial applications. Our warranty will be

voided if the equipment is used in commercial,

trade or industrial businesses or for equivalent

purposes.

Only saw blades designed for the machine

should be used (HM or CV saw blades). Use of

HSS saw blades and cutting disks is prohibited.

To use the machine properly you must also

observe the safety instructions, the assembly

instructions and the operating instructions to be

found in this manual.

All persons who use and service the equipment

have to be acquainted with this manual and

must be informed about the machine’s potential

hazards. It is also imperative to observe the

accident prevention regulations in force in your

area.

The manufacturer will not be liable for any

changes made to the machine nor for any

damage resulting from such changes. The following

hazards may arise in connection with the machine’s

construction and design:

•

Contact with the saw blade in places where it

is not covered.

•

Reaching into the moving saw blade (cuts)

•

Recoil of workpieces and parts of workpieces

from the machine.

•

Expulsion of defective hard metal parts from

the saw blade

•

Damage to hearing if ear-muffs are not used

as necessary along with harmful emissions of

wood dust when used in closed rooms.