49

ADJUSTMENTS AND OPERA

ADJUSTMENTS AND OPERA

ADJUSTMENTS AND OPERA

ADJUSTMENTS AND OPERA

ADJUSTMENTS AND OPERATIONS

TIONS

TIONS

TIONS

TIONS

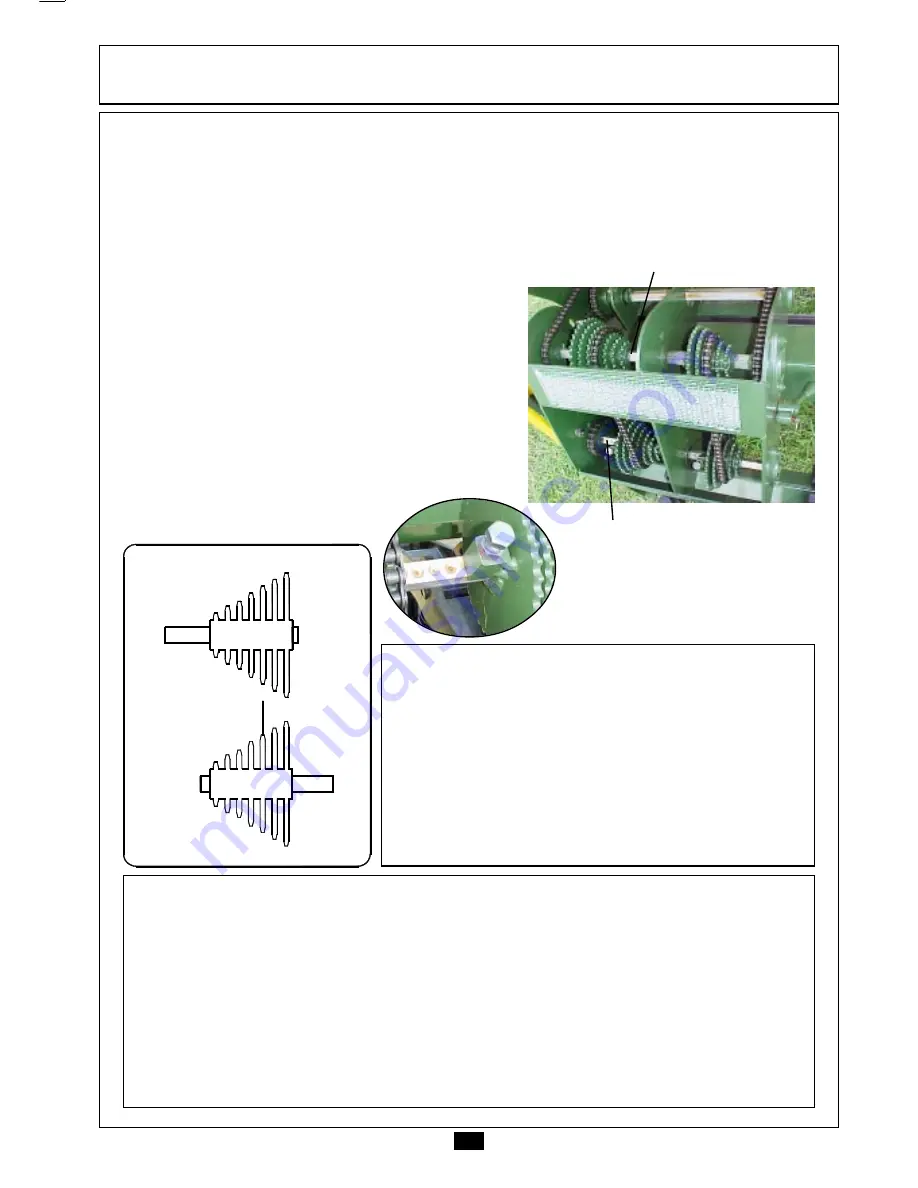

Fertilizer Distribution - Calibrating

The fertilizer distribution is done through the steel auger type dispensers, and the

different rates are adjusted by the sprocket combinations of the Drive Shaft {

C

} (14-, 18-

, 22-, 26-, 30-, 34- and 38-tooth) and Driven Shaft {

D

} (14-, 18-, 22-, 26-, 30-, 34- and 38-

tooth).

Procedures for the Sprockets

Handling

- Move the lever to alleviate the chain

tightener and lock with the pin in the hole.

- Move the cone of sprockets in the shaft,

aligning the chosen sprocket and the chain.

- Loosen the lever liberating the lock pin.

IMPORTANT

FIND ON THE PAGE 51 THE DIFFERENT FERTILIZER RATES FOR SEVERAL ROW

SPACINGS, ACCORDING TO THE SPROCKET COMBINATIONS.

THE SEED AND FERTILIZER DISTRIBUTION TABLES OF THIS MANUAL, SHOULD BE USED

AS A REFERENCE TO START THE PLANTER CALIBRATION. FACTORS AS SLIPPAGE

INDEX OF THE PLANTER CARRYING-WHEELS (SKIDDING), WORKING SPEED, TIRES

INFLATION AND FIELD CONDITIONS CAN INTRODUCE VALUES A LITTLE DIFFERENT

FROM THOSE INDICATED IN THE TABLES. THEREFORE, IT IS ALWAYS INDISPENSABLE

TO MAKE THE PRACTICAL DISTRIBUTION TESTS AS INDICATED ON THE PAGE 52 OF

THIS MANUAL.

Note: - THE CONE BOLTS ON THE SPROCKETS

HANDLING "TRA" ARE PRE-ADJUSTED ON THE

FACTORY, ALLOWING CHANGE OF THE

SPROCKETS WITHOUT USE OF TOOLS. IN CASE

OF ANY SLIDING MOTION ON CONE SHAFT,

JUST RELEASE THE COUNTER NUT AND TURN

AROUND THE BOLT TO RE-LOCK.

IN ORDER TO AVOID DAMAGE TO THE SPRING

AND SHAFTS NEVER APPLY EXCESSIVE

TORQUE WHEN TIGHTENING.

14

26

30

34

38

"C"

SHAFT

DRIVE

22

18

FERTILIZER

SPROCKET COMBINATIONS

14

38

18

22

34

30

26

"D"

SHAFT

DRIVEN

DRIVE SHAFT (C)

DRIVEN SHAFT (D)