©Copyright Task Force Tips LLC 2010-2021

8

LIU-330 February 15, 2021 Rev09

5.4 FOAM SUPPLY LOGISTICS

The foam suction hose is matched to the eductor and must not be lengthened. Lengthening the foam suction hose reduces foam flow,

resulting in weak foam. Position foam buckets within reach of the standard length foam suction hose.

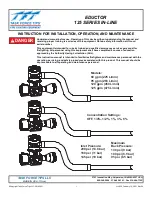

6.0 MAXIMUM HOSE LAY

The maximum hose lay is based on the back pressure. Pushing the foam solution through the hose and eductor causes back pressure

on the eductor exit.

• On a 200 psi (13.8 bar) model, if the back pressure is over 130 psi (9 bar) the eductor will not work.

• On a 160 psi (11 bar) model, if the back pressure is over 100 psi (6.9 bar) the eductor will not work.

• On a 145 psi (10 bar) model, if the back pressure is over 95 psi (6.5 bar) the eductor will not work.

Elevation loss adds to the back pressure when the nozzle is higher than the eductor. For each foot in vertical height, there is 0.4 psi

elevation loss.

Friction loss varies with different brand hoses. Determine the friction loss of your own hose. The nominal flow of the eductor is the sum

of water plus foam concentrate when set at 6%. The eductor should always have its rated pressure at the inlet. The water flow does not

change with different percentage settings; however, the inducted foam concentrate will change when the percentage setting is changed.

Therefore, the total flow exiting the eductor is lower at 1/4% than at 6%. Longer hose lengths can be used when proportioning rate is

less because less work is needed to move lower total flows.

7.0 NOZZLE SELECTION

Eductors work with any nozzle whose gallonage is equal or greater than that of the eductor. If a nozzle with a larger gallonage is used,

the reach of nozzle and the proportioning rate of the eductor will be compromised.

Non-aspirated automatic nozzles can produce expansion ratios of 6-8:1 when measured at the end of the stream. By maintaining a

constant nozzle pressure, automatic nozzles keep the velocity of the stream high. Large amounts of air are pulled into the stream and

mix with the foam concentrate/water solution as the stream leaves the nozzle.

Air-aspirating devices, such as the TFT FOAMJET, allow a wider selection of foam concentrates to be used, and can produce a better

quality of finished foam. The final expansion ratio and, amount of finished foam, depends on the type of foam concentrate being used.

DANGER

Lack of foam can place operator at risk of injury or death. To reduce the risk of injury due to lack

foam:

• Establish foam flow before advancing into hazardous situations.

• Keep an adequate supply of foam concentrate on hand.

• Check concentrate level periodically.

WARNING

Excess back pressure causes loss of foam flow resulting in risk of injury or death from an

ineffective stream.

• Verify that adequate foam flow is established and maintained.

• Do not exceed the maximum back pressure.

WARNING

Excess back pressure causes loss of foam flow resulting in risk of injury or death from an

ineffective stream. Operate the nozzle fully open to prevent excessive back pressure.