©Copyright Task Force Tips LLC 2010-2021

15

LIU-330 February 15, 2021 Rev09

9.0 MAINTENANCE

The Eductor must be completely cleaned after each use. Lack of regular cleaning allows the foam concentrate to dry inside and around

the percentage ball resulting in plugged metering orifices. Look down inside the metering head after flushing and check valve to ensure

clean passageways.

9.1 SERVICE TESTING

In accordance with NFPA 1962, equipment must be tested a minimum of annually. Units failing any part of this test must be removed

from service, repaired and retested upon completion of the repair.

9.2 REPAIR

Factory service is available with repair time seldom exceeding one day in our facility. Factory serviced equipment is repaired by

experienced technicians, wet tested to original specifications, and promptly returned. Any returns should include a note as to the nature

of the problem and whom to reach in case of questions.

Repair parts and service procedures are available for those wishing to perform their own repairs. Task Force Tips assumes no liability for

damage to equipment or injury to personnel that is a result of user service. Contact the factory or visit the web site at tft.com for parts

lists, exploded views, test procedures and troubleshooting guides.

Performance tests shall be conducted on the equipment after a repair, or anytime a problem is reported to verify operation in accordance

with TFT test procedures. Consult factory for the procedure that corresponds to the model and serial number of the equipment. Any

equipment which fails the related test criteria should be removed from service immediately. Troubleshooting guides are available with

each test procedure or equipment can be returned to the factory for service and testing.

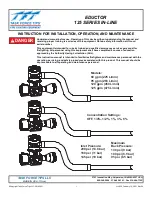

10.0 TROUBLE SHOOTING

Table 10.0

11.0 EXPLODED VIEWS AND PARTS LISTS

Exploded views and parts lists are available at tft.com/serial-number.

CAUTION

Any alterations to the product or its markings could diminish safety and constitutes a misuse of

this product.

NOTICE

All replacement parts must be obtained from the manufacturer to assure proper operation of the

device.

SYMPTOM

POSSIBLE CAUSE

REMEDY

Eductor picks

up too much

foam

concentrate

Percentage Knob is set at higher percentage than desired

Turn knob to desired percentage

Eductor inlet pressure is incorrect

Set eductor inlet pressure to pressure specified on

labels

Metering head paired with incorrect body

Use correct metering head for body

Weak Foam or

No Foam

Out of foam or bucket is nearly empty

Refill tank

Percentage knob is set to lower percentage or is set to OFF Turn knob to desired percentage

Percentage ball is partially or completely plugged

Take off the meter head and clean debris out of the

percentage ball

Hose lay is incorrect

Correct hose lay per training approved by the AHJ

Eductor inlet pressure is incorrect

Set eductor inlet pressure to pressure specified on

labels

Hose is kinked

Straighten kinks out of hose

Concentrate intake hose is completely or partially clogged

Clean debris out of concentrate intake hose

Valve in nozzle is not fully open

Fully open valve in nozzle

Nozzle size is incorrect

Select correct nozzle

Nozzle is clogged

Flush nozzle to clear out debris or remove nozzle to

clean debris out

Foam has thickened due to cold temperatures

Use a foam suitable for temperatures