64

BWC Hydraulic Feed Wood Chipper

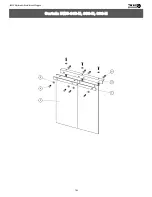

BWC Decals

1

-

D1015 Decal Logo

“

Tar River

”

2

-

Decal Model #

3

-

RT1007 Decal Danger Rotating

4

-

P960 Decal Warning

8

-

Z94007 Decal Danger

“

Rotating Blades

”

7

-

Z94008 Decal Danger

“

Thrown Object Hazard

”

6

-

9270112 Decal Caution

“

Avoid

5

-

Z94006 Decal Caution

“

Read Manual

”

10

-

Z94005 Decal Warning

“

High Pressure

”

11

-

Z94005 Decal Warning

“

High Pressure

”

9

-

Z94005 Decal Warning

“

High Pres-

12

-

D1322 Decal Danger

“

Keep Hands/Feet Out of Hopper

”

13

-

Decal Serial Tag

Summary of Contents for BWC Series

Page 1: ...Rel 02 24 Wood Chipper BWC Series Hydraulic Feed Operator s Manual...

Page 2: ...2 BWC Hydraulic Feed Wood Chipper Page left blank intentionally...

Page 29: ...Rel 02 24 Wood Chipper BWC Series Hydraulic Feed Parts Manual...

Page 42: ...42 BWC Hydraulic Feed Wood Chipper Discharge Chute BWC 040 H 060 H 080 H...

Page 44: ...44 BWC Hydraulic Feed Wood Chipper Feed Chute BWC 040 H...

Page 46: ...46 BWC Hydraulic Feed Wood Chipper Feed Chute BWC 060 H 80 H...

Page 48: ...48 BWC Hydraulic Feed Wood Chipper Feed Roller BWC 040 H 060 H 080 H...

Page 50: ...50 BWC Hydraulic Feed Wood Chipper Flywheel BWC 040 H...

Page 52: ...52 BWC Hydraulic Feed Wood Chipper Flywheel BWC 060 H...

Page 54: ...54 BWC Hydraulic Feed Wood Chipper Flywheel BWC 080 H...

Page 56: ...56 BWC Hydraulic Feed Wood Chipper Curtain BWC 040 H 060 H 080 H...

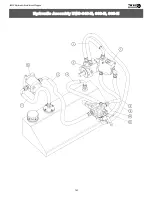

Page 58: ...58 BWC Hydraulic Feed Wood Chipper Hydraulic Assembly BWC 040 H 060 H 080 H...

Page 62: ...62 BWC Hydraulic Feed Wood Chipper BWC Decals...

Page 66: ...66 BWC Hydraulic Feed Wood Chipper Page left blank intentionally...

Page 67: ...67 BWC Hydraulic Feed Wood Chipper Page left blank intentionally...