3

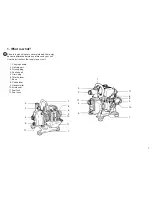

Before operation

On fuel

NOTE!

NOTE!

Helpful information for correct function and use.

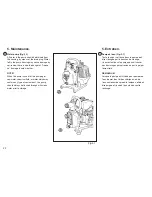

During operation

WARNING!

Indicates a strong possibility of severe

personal injury or loss of life, if instructions are

not followed.

CAUTION!

Indicates a possibility of personal injury or

equipment damage, if instructions are not

followed.

2. Warnings and safety instructions.

Protection is required for head, eyes, ears,

hands and feet. Wear a suitable hard hat,

goggles, ear covers, heavy gloves and safety

shoes.

Dress properly, do not wear loose clothing or

jewelry that could become caught in moving

parts of the unit.

Never let a child or inexperienced person

operate the machine.

Be sure to check bolts and other fasteners to

see if any of them have become lose or are

missing.

Empty the fuel tank before storing the

tool. Especially, in case of over three

month storage, it is essential as fuel may

corrode causing carburetor damage. It is

recommended that the fuel be emptied

after each use. If fuel is left in the tank,

store so fuel will not leak.

Never operate the engine with gasoline only.

This engine uses a fuel mix of 25-50 parts

regular gasoline to 1 part of two-stroke oil.

The fuel should be premixed prior to pouring

into the fuel tank. It is recommended quality

two-stroke oil be used in the fuel mix.

Failure to mix oil with gasoline will result in

seizure and severe damage to the engine.

Do not use gasoline containing alcohol or

gasohol.

Do not smoke when the fuel is supplied, and

when you are working with the machine.

Do not touch tank cap or fill the fuel tank

while the engine is running or still warm. The

fuel should be poured into the fuel tank when

the engine is cold.

Never start the machine without priming water

in the pump. It will cause serious damage to

the engine and the pump. The manufacturer

cannot guarantee in this case.

Care must be taken to ensure that an air

tight connection is made between the female

unions, and the male pump stubs. An air leak

at either union will greatly reduce the pump

efficiency, or no water is pumped at all.

A strainer should always be used on the

suction hase, to prevent debris from entering

the pump body, and causing possible damage

to the impeller.

The unit should be operated in well

ventilated area.

Never carry the unit with the engine running.

For safety, the unit should not be started

without priming water.

Do not pump oil etc, which is flammable.

After the pumping of seawater, chemical fluid

or urine, wash the pump with fresh water.

En