www.tamcodampers.com

© T.A. Morrison & Co. Inc., 2020

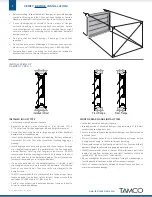

Backdraft

Damper Blade

Linkage

Rod

Zert Nut

Adjustable

Weight

Weight

Locking Nut

Adds more

resistance

to opening

SERIES 7000 WT

>

Series 7000 WT Weighted Backdraft Dampers have a round,

adjustable weight and a threaded post secured to the center of

each blade. A zert nut on the back of the blade is used to lock the

threaded post in place.

>

Each cylindrical, steel weight measures 1¼”

(32 mm)

in diameter.

>

Weights are supplied, so that the required resistance to the

opening of the blade against airflow can be achieved.

>

The cylinder can be adjusted away from or towards the blade, as

far as the threaded post will allow.

>

Moving the weight away from the blade will increase the amount

of additional pressure and airflow required to open the backdraft

damper blades.

>

Moving the weight closer to the blade will decrease the amount of

additional air pressure and airflow required to open the backdraft

damper blades.

>

Additional weights may be added to increase the desired pressure

build-up before the backdraft damper begins to open.

>

Adjust weight placement until desired pressure build-up is

achieved.

(Several re-adjustments may be necessary for desired

operation.)

>

Once adjustment is completed, tighten the weight locking nut to

prevent weight from moving out of position.

SERIES 7000 CW

>

Series 7000 CW Counterweighted Backdraft Dampers have an

adjustable ¾” wide

(19 mm)

aluminum, counterweight bar attached to

the back of the blades

(with the exception of the top blade)

.

>

The aluminum bar bracket is centered along the length of the

blade. This is designed to apply even pressure across each blade.

Do not move the bar bracket away from the factory-aligned center

of the blade.

>

Counterweights can be set to relieve air pressure differentials less

than .01 in. w.g.

(3 Pa)

.

>

To accelerate blade opening, move the aluminum counterweight

bar further away from the blade.

>

To delay blade opening, move the aluminum counterweight bar

closer to the blade.

>

To move the aluminum counterweight bar, first loosen the two

socket head cap screws with a

3

/

16

”

(4.8 mm)

Allen/Hex wrench.

Do not remove the screws. (

The socket head cap screws secure the

aluminum counterweight bar in place, through the washer and the

aluminum bar bracket.)

>

Slide the aluminum counterweight bar in the direction required to

achieve desired blade operation. The counterweight bars should

be adjusted to the same location on each blade, to ensure that

even pressure is applied across the entire backdraft damper.

(Several re-adjustments may be necessary. Keep in mind that

depending on external conditions and damper size, moving the

aluminum bar to the furthest point away from the blade might

prevent the backdraft damper from closing.)

>

Once adjustment is completed, re-tighten socket head cap screws.

4

TAMCO MEDIUM-DUTY BACKDRAFT DAMPER |

Weight Adjustment

For Series 7000 WT & 7000 CW

Backdraft

Damper Blade

Linkage

Rod

Aluminum

Counterweight

Bar

Aluminum

Bar Bracket

Washer

Socket Head

Cap Screw

Acceler

ate

Dela

y