④

5

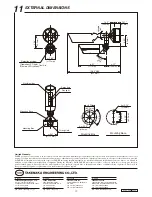

WIRING

COM

N.C.

N.O.

Mounting hole

(knock out)

United band

hole

Push rivet

Screw

Wiring hole

MOUNTING BOX

MOUNTING BASE

66.7mm

2.63

"

3.29

"

83.5mm

φ6×30 Tapping screw

Screw

Wall

Screw

(1) Attention

(2) Wiring Connection

Operation (selectable) :

Contact capacity : 30V (AC/DC)

0.5A or less

detection time + off delay operation

approx. 2 secs. ~ approx. 1 min.

or

detection time + off delay operation

approx. 5 secs. ~ approx. 10 mins.

Dry contact relay output Form C

Power

10V to 30VDC

(non-polarity)

35mA or less

6

The following wiring and installation can be done. Follow the procedures.

INSTALLATION

*

*

*

EXPOSED WIRING

BUILT IN WIRING

(1) Fix to the surface

(1)

(2)

(2)

(3)

(3)

(4)

blue

black

red

yellow

white

【

Wiring distance

】

Power supply

Size of wire used

DC12V

DC24V

1310' ( 400m)

3120' ( 950m)

5250' (1600m)

9800' ( 3000m)

22600' ( 6900m)

38000' (11600m)

NOTE : 1)

2)

0.75mm

2

(φ0.93mm)

1.25mm

2

(φ1.3 mm)

0.3 mm

2

(φ0.65mm)

Maximum wiring distance, when two or

more sets are connected, is calculated by

dividing the above value by number of sets.

The signal line can be wired in the

distance of up to 3,000ft. (1,000m) with

(dia. 0.65mm) telephone wire.

Select the most suitable installation place and way

according to the purpose. (Refer to "3. PRECAU-

TIONS" and the following)

Take off the 2 screws, mounting base, mounting box.

(Wiring leads are contained in the mounting base.)

Wire and instal the sensor.

(Refer to "5. WIRING"

and the following)

Set up temporary and confirm the area and operation.

①

Make a hole through the 4 mounting holes

(knock outs) by a driver etc.

②

Fix the mounting box by the 4

φ

6

×

30

tapping screws to the surface.

Fix the mounting base tightly to the

mounting box by the 2 screws.

Follow the "5. (2) Wiring connection" for wiring. To avoid direct

pressure to the knot, combine the wiring by the accessory Combin-

ing Band and fix it to the inside of the box by

φ

4

×

8 tapping screw.

Preparement (not necessary for following case)

[The mounting base fits 83.5mm and 66.7mm type

built in switch box. However, it needs adjustment

for the following case.]

◎

66.7mm type (beginning set up : 83.5mm)

・

Push out the 2 push rivets from the back side of

the mounting base and put them into the 2 holes

on the outside.

Follow the "5. (2) Wiring connection" for wiring.

Fix the mounting base tightly to the attachment

box by the 2 screws.

Give rain proof treatment such as calking to the top

and side of the mounting base. (It may not stick

according to the surface condition.)

*

Use optional equipments for other installation.

Take off the lid of the wiring hole on the bottom

of the mounting box and pass the wiring

through. (Conduit tube wiring is possible for

the wiring hole is conduit tube screw G16.)

(4)

Turn off power when installing. Hot line work will cause electric shock

and damage.

Lead wiring is required. Follow the proper way.

The wiring lead is contained in the mounting base. Take off the screw,

mounting base, and mounting box when installing.

[1]

[2]

[3]

[4]

Fixing hole

Conduit bushing

Wire connection

Combining band

Tapping screw

Lid