- 8 -

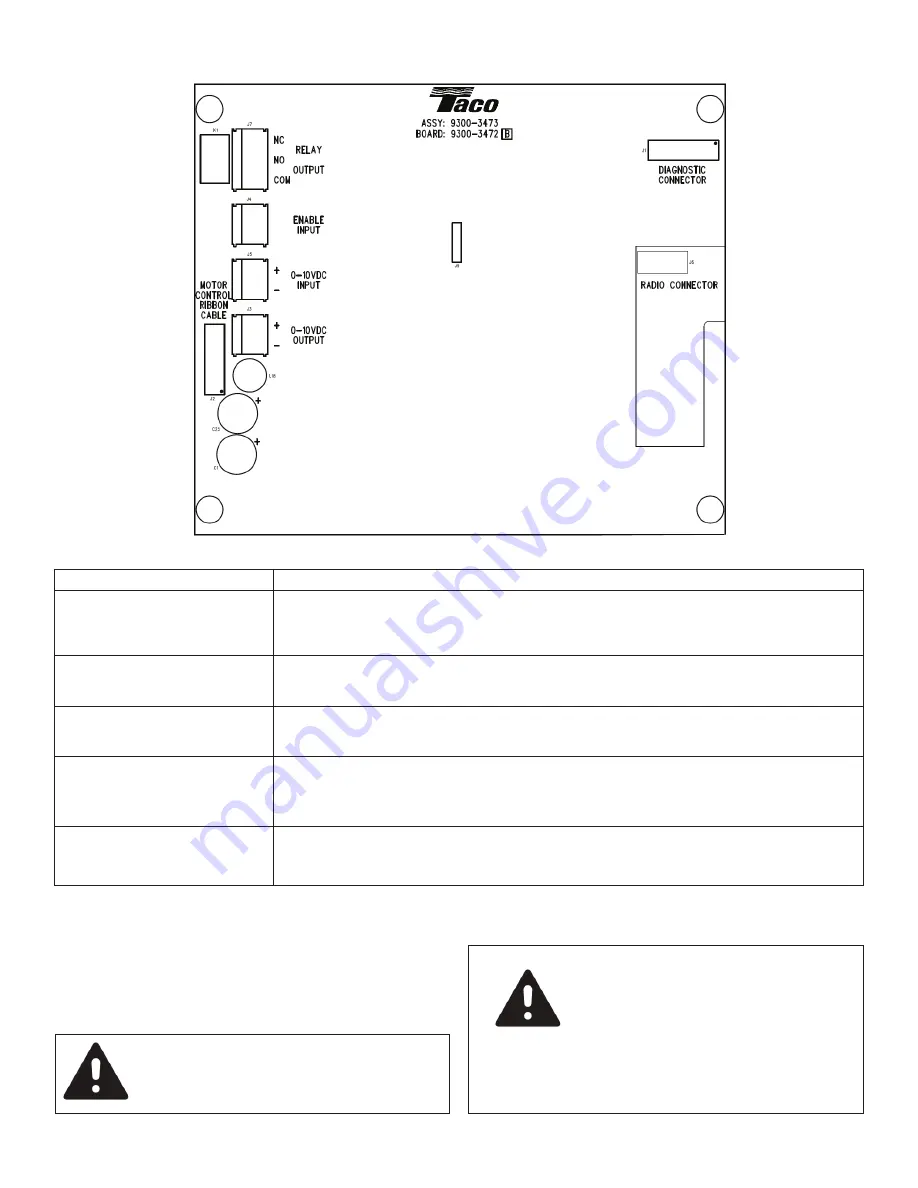

20 - Controller Layout

Terminal Designation

Description

RELAY OUTPUT

Used to enable alarm output, Relay is closed during normal operation and open during alarm.

Used to enable Lag pump when in 2 pump operation. The primary pump relay is used to turn

on/off the Lag pump through the slave enable input.

ENABLE INPUT

Jumper must be connected for pump to run. (DEFAULT CONFIGURATION)

Use with external DRY CONTACT RELAY ONLY for remote on/off

0 - 10V DC Input

Used to receive speed control from an external control.

Used to receive input from Slave pump when in 2 pump operation to verify operation.

0 - 10V DC Output

Used to send signal to Master in 2 pump operation

Used to provide analog feedback to an external controller

Note: Max output voltage may be limited due to power limiting of the pump.

MOTOR CONTROLLER

RIBBON CABLE

Connects High Voltage Power Module to UI. If the cable becomes disconnected, reconnect to

“MOTOR CONTROL RIBBON CABLE” connector.

21 - Connection Considerations

• All cables connected must be heat-resistant to at least +194 °F (90˚C)

• All cables connected must be installed in accordance with The National

Electric Code NFPA 79 / EN 60204-1.

• All wires to the communications module must be connected to the termi-

nals or cut. No loose wiring permitted.

Warning:

Voltages 24V AC/DC are possible

on NO, C, NC Terminals.

Cable outer layer must not be

stripped longer than 0.59 inches.

15 Vdc Maximum on 0-10 V DC

input and output terminals

Warning:

Before performing any work on the UI, make

sure that the pump and module electricity supply has been

switched off and that it cannot be accidently switched on.