9

SECTION #5 OPERATION OF THE TOUCH PANEL CONTROLLER CONTINUED:

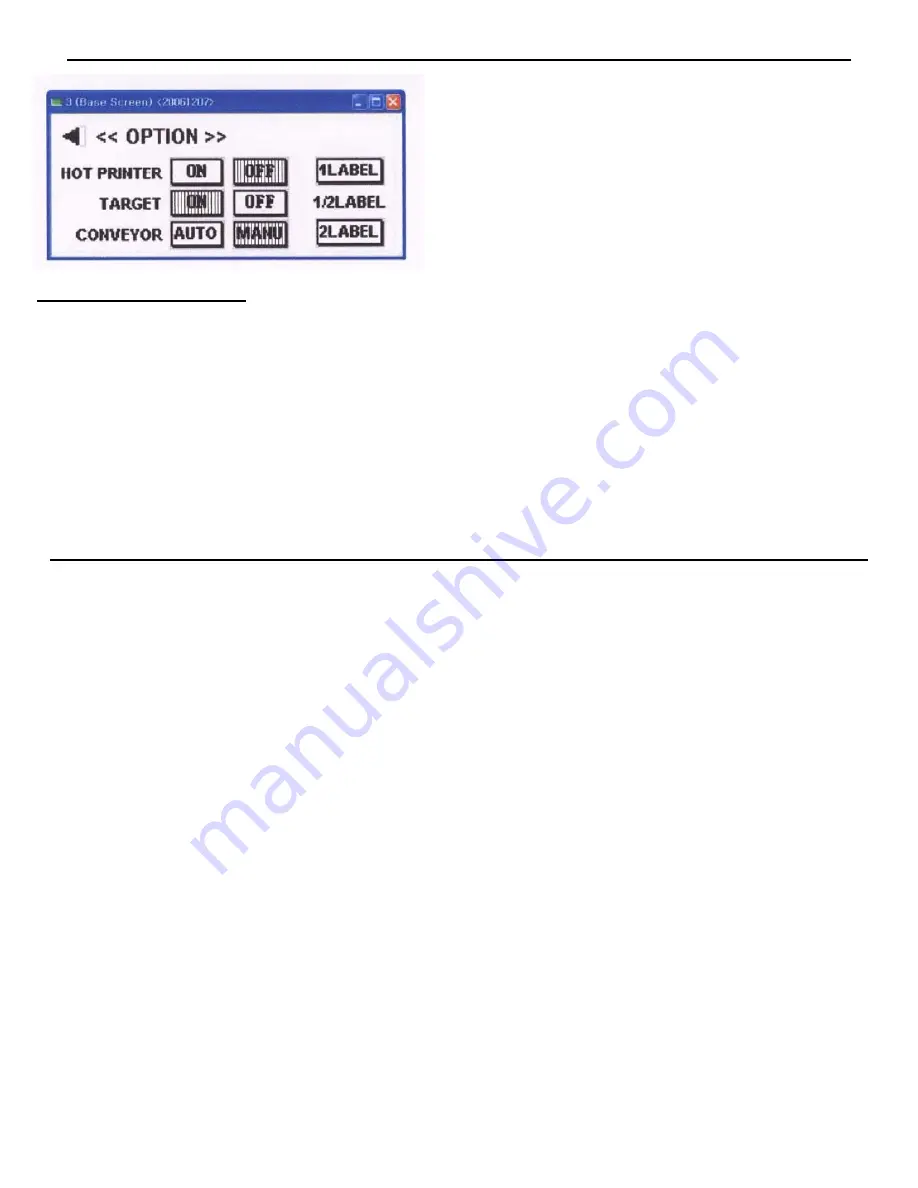

Figure #11

To Set the Target Counter:

1) To set the Target Counter, first turn the option on by going to the Option Sub Menu per the previous instructions

and touching the On box.

2) From the Home Screen, touch the box next to the word Target and an Numeric Keyboard will be displayed.

Input the desired number of packages to be labeled and touch the Enter button on the bottom right of the Numer-

ic Keyboard.

3) Begin to label the packages. When the pre-set Target count is completed, the screen on the Touch Panel

Controller will turn Red and no more packages will be labeled.

SECTION #6 OPERATION OF THE TACH-IT MINI-CON and MINI-CON-S LABELER:

1) Place the Labeler on a flat dry work surface near the proper voltage electric outlet.

2) Set up the Labeler and load the labels into the Labeler per the instructions in Sections 3 & 4 of this manual.

3) Plug the Labeler into the proper voltage electric outlet using the enclosed electric power cord which will go into

the IEC connection located on the rear of the Touch Panel Controller.

4) Turn the Power On by using the rocker switch located on the front of the Touch Panel Controller. If the Convey-

or does not begin to move, locate the Emergency Shut Off Button on the front of the Conveyor and pull it out.

5) Complete the set up described in Section #5 of this manual to utilize the options desired and to make sure that

label placement is where needed. If this is not correct, refer to Section #5 of this manual and make the necessary

changes.

6) Place a test product to be labeled onto the Conveyor and it should move forward and pass underneath the Main

Label Head where a label should be dispensed onto the product and the product should continue to the end of the

Conveyor. If the placement of the label is not correct, review Section #5 of this manual and make the necessary

changes to the Start Delay and Motor Speed of the Labeler and retry until proper placement is achieved. If the

label is dispensed in the proper place, but not wiped down, use an allen screw and adjust the brush located to the

right of the dispensing plate. This brush should have light contact with the top of the package as it moves along

the conveyor. If the labels do not feed properly check Section #4 of this manual and confirm that the labels are

properly loaded and that the Urethane Wiper or the Urethane over the dispensing plate is not causing to much

tension to the label. If the label is not dispensing, tension made need to be added to the Urethane Wiper or the

Urethane above the dispensing plate. If the labels continue to run and more than 1 label is fed, see Section #7 on

the following page for instructions on adjusting the sensitivity of the Stop Sensor.

Summary of Contents for Mini-Con

Page 12: ...12 SECTION 9 PARTS LIST...