Page 21

English

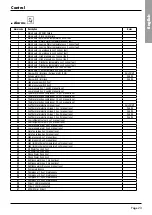

Control

6 GENERAL INFORMATION

Introduction

This document contains the information and the oper-

ating instructions for 4 compressors & electronic

control.

This information is for the after-sales service and the

production operators.

Main characteristics

– Microprocessor control

– User-friendly keyboard

– Proportional and integral control of the return

water temperature (RWT)

– Hysteresis control of the leaving water temperatu-

re (LWT)

– Access code to enter the Manufacturer’s Level

– Access code to enter the Assistance Level

– Alarm and LED

– Backlighted LCD

– Pump-Down logic

– Rotation of the compressor operation

– Oil return function

– Night mode (or Low Noise) control

– Counting of the pump/compressors’ hours of

operation

– Display of discharge and suction pressure values

– Display of temperature sensor

– History of stored alarms (option)

The following accessories can be also connected:

– Remote Display Terminal

– Wire Remote Control

6.1 Control of VLH-VLC

with 4 compressors.

The “CHILLER CONTROL” system

The machines with 4 scroll compressors are provided

with a microprocessor card which is fully programmed

by default for the control of a chiller of cold only type

with 2 circuits, 2 compressors per circuit, a high-pres-

sure transducer per circuit.

The control system consists of:

Keyboard & Display Terminal

General information

The figure shows the terminal with the front door open.

It is provided with a LCD 8 lines x 22 columns, key-

board and microprocessor-controlled LED’s, so as to

allow the programming of the control parameters (set-

point, differential bands, alarm thresholds) and the

main operations to be carried out by the user.

Terminal & Key Board description

The terminal makes it possible to carry out the follow-

ing operations:

– the initial configuration of the machine

– the change of all the main operating parameters

– the display of the detected alarms

– the display of all the measured quantities

The terminal and the card are connected by a 6-way

phone cable.

The connection of the terminal to the basic card is not

essential for the normal operation of the controller.