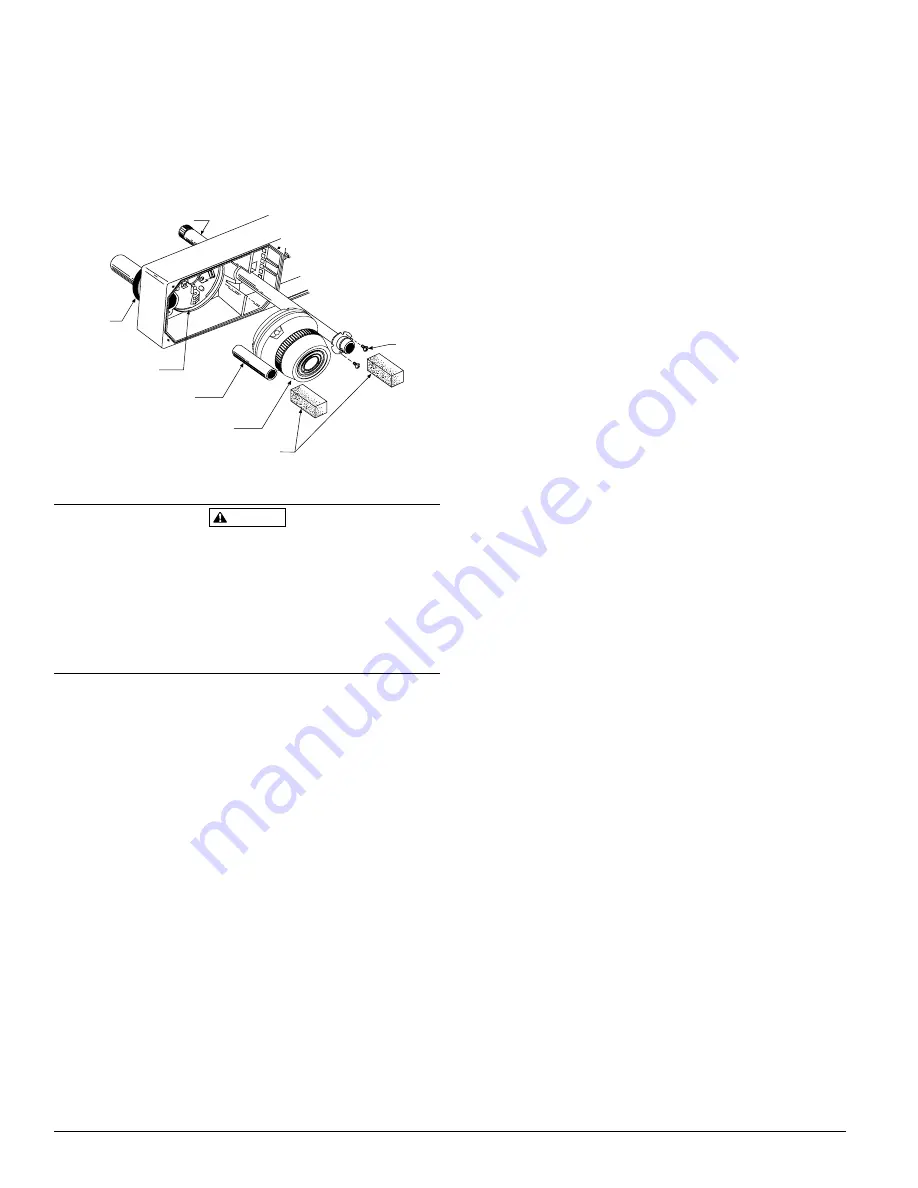

[5.6] Install The Filters

To install the sampling tube filters, simply push the filter

adapter into the exhaust tube, and then push the filter onto

the adapter tube on the left, as shown in Figure 8. Then in-

stall the other filter over the end of the inlet sampling tube.

Figure 8. Sampling tube filter installation:

SAMPLING TUBE

FILTERS

SAMPLING TUBE

MOUNTING

SCREWS

DETECTOR HEAD

EXHAUST

FILTER ADAPTER

DETECTOR BASE

INLET SAMPLING TUBE

FOAM GASKET

A78-2106-01

CAUTION

Filters require periodic cleaning or replacement, depending

on the amount of dust and dirt accumulated. Visually in-

spect the filters at least quarterly; inspect them more often

if the dust accumulation warrants it. See Section [6] for

more information. Replacement filters can be ordered from

System Sensor, 3825 Ohio Ave., St. Charles, IL 60174. (Ex-

haust tube/intake tube filter P/N F36-05-00)

[5.7] Perform Detector Check

1. Perform STANDBY AND TROUBLE TEST per Section

[6.2.1].

2. Perform MAGNET TEST per Section [6.2.2.1]. The

RTS451 test of Section [6.2.2.2] may substitute for this

requirement.

3. Perform AIR FLOW TEST per Section [6.1.1].

4. Perform SMOKE RESPONSE TEST per Section [6.1.2].

5. Perform SENSITIVITY TEST per Section [6.2.3].

6. Record all test results in the DETECTOR TEST LOG pro-

vided with this manual.

[5.8] Install The Cover

Install the cover using the four screws that are fixed in the

housing cover. Be certain filters are installed as specified in

Section [5.6]. Make sure that the cover fits into the base

groove and that all gaskets are in their proper positions.

Tighten the four cover screws to 10 in-lbs.

[6] Duct Detector Maintenance And Test Procedures

Test and maintain duct detectors as recommended in NFPA

72. The tests contained in this manual were devised to as-

sist maintenance personnel in verification of proper detec-

tor operation.

Before conducting these tests, notify the proper authorities

that the smoke detection system will be temporarily out of

service. Disable the zone or system under test to prevent

unwanted alarms.

After conducting these tests, record the appropriate infor-

mation in the DETECTOR TEST LOG provided with this

manual.

[6.1] Smoke Entry Tests

[6.1.1] Air Flow

To verify sufficient sampling of ducted air, use a manom-

eter to measure the differential pressure created from air

flow across the sampling tubes. The pressure should mea-

sure no less than 0.01 inches of water and no greater than

1.20 inches of water.

[6.1.2] Smoke Response

To determine if smoke is capable of entering the sensing

chamber, visually identify any obstructions. Plug the ex-

haust and inlet tube holes to prevent ducted air from carry-

ing smoke away from the detector head, then blow smoke

such as cigarette, cotton wick, or punk directly at the head

to cause an alarm. REMEMBER TO REMOVE THE PLUGS

AFTER THIS TEST, OR THE DETECTOR WILL NOT FUNC-

TION PROPERLY.

D400-14-00

8

I56-554-05

Summary of Contents for DH400

Page 14: ...NOTES D400 14 00 14 I56 554 05 ...