SS-400-012 4 I56-3749-006

TABLE 1. TERMINAL DESIGNATIONS

NUMBER

NAME

TERMINAL BLOCK

T1

External Power -

1

T2

External Power -

T3

External Power +

T4

External Power +

T5

N/A

2

T6

N/A

T7

N/A

T8

N/A

T9

Alert NO

3

T10

Alert COM

T11

Alert NC

T12

Action 1 NO

4

T13

Action 1 COM

T14

Action 1 NC

T15

Action 2 NO

5

T16

Action 2 COM

T17

Action 2 NC

T18

Fire 1 NO

6

T19

Fire 1 COM

T20

Fire 1 NC

T21

Fire 2 NO

7

T22

Fire 2 COM

T23

Fire 2 NC

T24

Minor Fault NO

8

T25

Minor Fault COM

T26

Minor Fault NC

T27

Urgent Fault NC

9

T28

Urgent Fault COM

T29

Urgent Fault NO

T30

Isolate NO

10

T31

Isolate COM

T32

Isolate NC

T33

Ext Monitor/Reset -

11

T34

Ext Monitor/Reset -

T35

Ext Monitor/Reset +

SYSTEM POWERING

The following procedure describes how to initially power up the FAAST system.

CABLING REQUIREMENTS

The FAAST system provides a series of Euro style pluggable terminals, located

behind the left side door of the unit.

Refer to Table 1 for the proper electrical connections to the unit. Refer to Table

2 for a typical connection for monitoring the FAAST system at a Fire Alarm

Control Panel (FACP).

1. Unplug the unit’s power connector to the unit before turning ON the

power.

2. Turn on the power.

3. Check the voltage at the connector. Make sure it is within the required

voltage range.

4. If the voltage is within the proper range, reconnect the power connector

to the unit.

5. Verify the system fan starts up and air begins to flow out of the exhaust port.

6. Connect a computer, with the PipeIQ software installed, to the unit using

the Ethernet connection on the bottom of the unit.

7. Use the PipeIQ software to set up the unit configuration required for the

particular application.

8. When the configuration is complete, remove the Ethernet connection to

the unit.

USER INTERFACE

The user interface, shown in Figure 4, provides the following information:

• Detector Status: Normal, Alarm, Fault or Isolate

• Alarm Level; Alert, Action 1, Action 2, Fire 1 and Fire 2

• Particulate Levels; 1-10 relative to Alert

• Fault Status

• Flow Level

• Test, Reset and Isolate Buttons

USER INTERFACE CARD INSTALLATION

The user interface card must be installed on the front panel of the FAAST

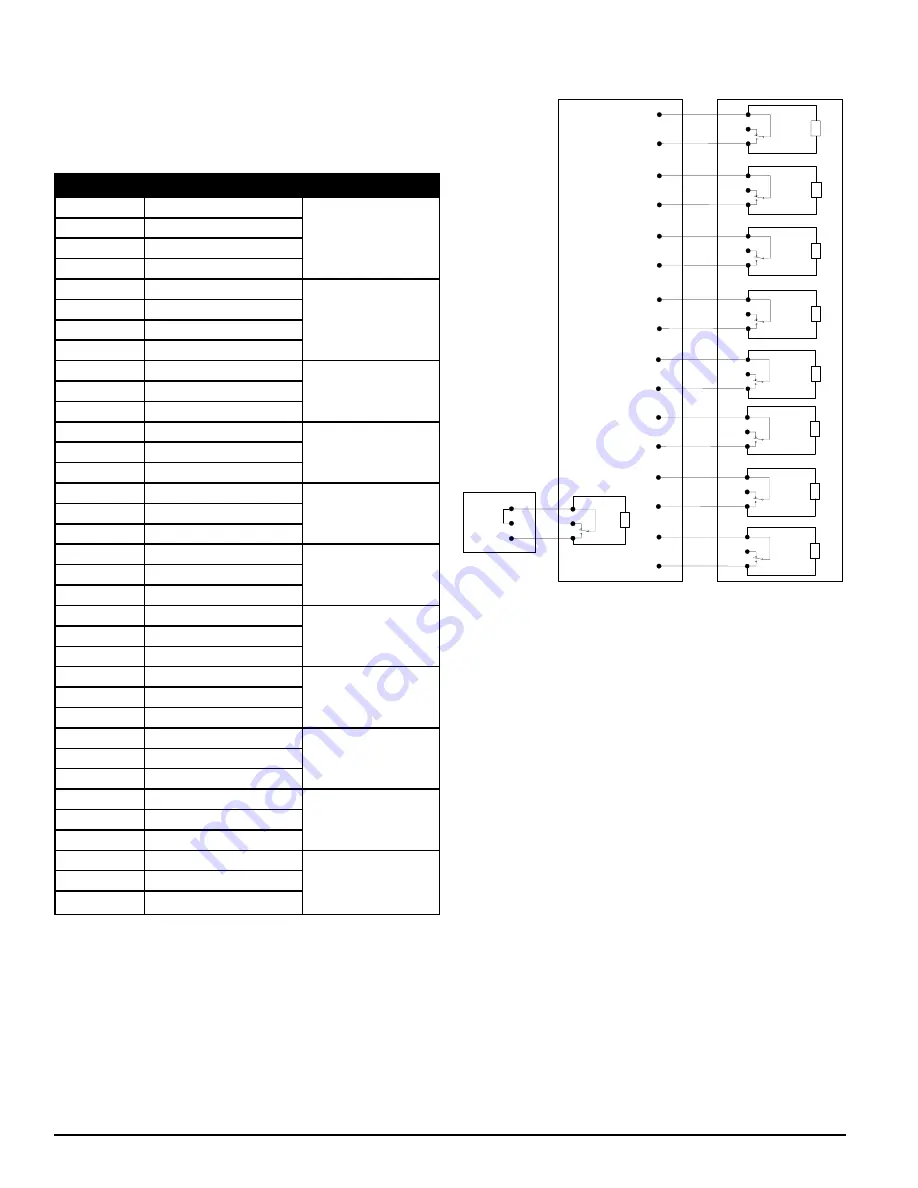

TABLE 2. FACP WIRING DIAGRAM

ASP18-01

N.C.

N.O.

C.

Fire2 Relay Contact

s

(T7)

Fire Panel (FACP) typical connection

FAAST 8100A

Fire Alarm Aspiration Sensing Technology®

FAAST 8100A

Fire Alarm Aspiration Sensing Technology®

for monitoring of device

Alarm

Short = Fire

Open = Fault

EOL

N.C.

N.O.

C.

Fire1 Relay Contacts

(T6)

Alarm

Short = Fire

Open = Fault

N.C.

N.O.

C.

Action2 Rela

y

Contacts

(T5)

Alarm

Short = Fire

Open = Fault

N.C.

N.O.

C.

Action

1

Rela

y

Contacts

(T4)

Alarm

Short = Fire

Open = Fault

N.C.

N.O.

C.

Alert Relay

Contacts

(T3)

Alarm

Short = Fire

Open = Fault

N.C.

N.O.

C.

Isolate Relay

Contacts

(T10

)

Supervisory

Short = Isolate

Open = Fault

N.C.

N.O.

C.

Urgent Relay

Contacts

(T9)

Short = Urgent Fault

Open = Fault

N.C.

N.O.

C.

Minor Relay

Contacts

(T8)

Short = Minor Fault

Open = Fault

N.C.

N.O.

C. (Reset)

Panel

Remote

Reset

-

-

+

Monitor

Short = Reset

Open = Fault

FACP

Supervisory

Supervisory

EOL

EOL

EOL

EOL

EOL

EOL

EOL

EOL

47K