9

COMMISSIONING AND MAINTENANCE

PWM input signal

With a low input value (<5 % PWM), the pump cannot start.

The pump stops when input signal is 5 to 8% of PWM signal

or when PWM signal is not present, for safety reasons. If

the pump receives no input, due for instance to failure of

the signal cable, it will stop in order to avoid solar system

overheating.

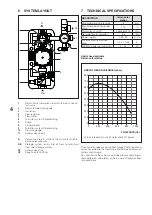

Speed (%)

0 5 10

100

20 30 40 50 60 70 80 90 100

PWM input signal (%)

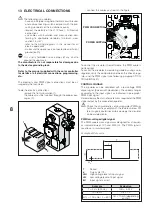

Electronic circuit

PWM output

PWM input

Reference

signal

Opto-isolator

Pump electronics

Technical specifications

Maximum power

Symbol

Value

PWM input frequency

f

100-4000 Hz

Consumption in stand-by

< 1 W

High voltage level of input

signal

UiH

4-24 V

Low voltage level of input

signal

UiL

< 1 V

Input signal current

IiH

< 10 mA

Input Duty cycle

PWM

0-100%

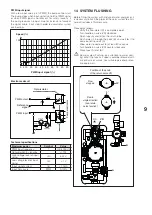

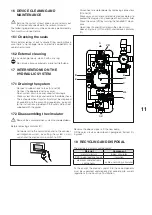

14 SYSTEM FLUSHING

Before filling the system with mixture of water and glycol, it

is necessary to flush the pipes of the solar system to elimi-

nate all residues of fluid or scale.

Proceed as follows.

- Verify the flow-meter (C) is completely open

- Turn handle on valve (VR) clockwise

- Open taps (A) and (B) on the return tube

- Flush water in through the cock (B) and wait for it to

come out of the cock (A)

- Allow water to come out for at least 30 seconds

- Turn handle on valve (VR) counter clockwise

- Close taps (A) and (B).

b

During system flushing, pay attention to water com-

ing out of the taps as vapour could be released with

risk of burns or scalds. Use suitable personal protec-

tive equipment.

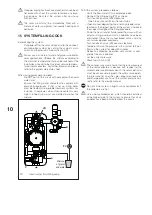

A

VR

B

RC

90°

0°

R

Position of the knob

of the return valve VR

Flow in

single direction

(non-return

valve function)

Flow

stopped

Commissioning and maintenance