GB.GOLDLP.170830

8 www.swegon.com

We reserve the right to alter specifications without notice.

4.3 To Adjust the Pressure Balance

4.3.1 General

There should be a certain degree of negative pressure in

the extract air section so that the direction of air leakage

through the heat exchanger and the function of the purg-

ing sector will be correct. This ensures that extract air will

not be transferred to the supply air.

The pressure balance in the unit should be adjusted when

the ventilation system has been fully installed and the

airflows discharged from all the air diffusers and registers

have been adjusted, and when the supply air and extract

airflows are as they should be while the air handling unit is

operating normally.

4.3.2 To Ensure the Correct Leakage Direction

The pressure balance in the AHU is adjusted by reposition-

ing a commissioning plate mounted in the extract air inlet.

The commissioning plate is supplied separately and should

be fitted by the fitter when the extract air duct is con-

nected. See illustration.

Connect a pressure gauge to the pressure measurement

tappings of the air handling unit. The AHU has four pres-

sure measurement tappings. The two tappings closest

to the extract air duct should be used. The blue pressure

measurement tapping is used for measuring the negative

pressure in the extract air section and the white pressure

measurement tapping is used for measuring the negative

pressure in the supply air section.

The pressure measurement tappings are situated by the

junction hood.

Note that both pressure measurement tappings are used

for measuring negative pressure.

MEASURED VALUES

The negative pressure in the extract air section should be

greater or the same as the negative pressure in the supply

air section.

If the negative pressure in the extract air section is the

same or up to 20 Pa greater than the negative pressure in

the supply air section, then you have finished commission-

ing the unit.

DEVIATIONS

If the negative pressure in the extract air section is less

than that in the supply air section, then you must carry out

the following adjustment:

1. Stop the air handling unit, open the inspection door to

access the extract air filter.

Blank off an appropriate number of holes in the com-

missioning plate using the plastic plugs supplied.

3. Close the inspection door and restart the AHU.

4. Measure the pressures.

Repeat this procedure until the negative pressure in the

extract air section is just as great or up to 20 Pa greater

than the negative pressure in the supply air section

(0–20 Pa).

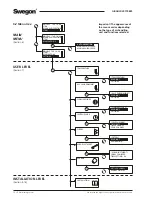

Pressure measurement tappings – leakage direction

(AHU shown in the right-hand version)

- (blue)

+ (white)

EXTRACT AIR

2

Commissioning plate

5. If the negative pressure in the extract air section is

greater than 20 Pa compared with the supply air sec-

tion, although the commissioning plate is dismantled,

the leakage and purging air flow will be greater than

anticipated. This means that the actual extract air flow

will deviate from the preset extract airflow. The devia-

tion increases as the difference in pressure increases.