D.Use of a roller fairlead will help

guide the rope onto the drum

and prevent the rope from rub-

bing against the mounting system

or castings. This prevents the

rope from damaging itself or

the winch.

E. Do not allow the wire rope to

contact the ground, rocks, or

anything other than approved

tackle during the winching

process.

F. Do not hook the wire rope back

onto itself. Use a sling or chain to

connect to the load.

G.Always protect your hands by

wearing leather or leather

palmed gloves when handling

wire rope. Never let the rope

slide through your hands. Instead

use a hand-over-hand motion to

feed the wire rope.

FREESPOOLING

Freespooling occurs when the drum

is disconnected from the gearbox

and/or out-put drive allowing the

wire rope to be removed from the

drum without supplying power to

the winch motor.

NEVER ATTEMPT TO PLACE THE

DRUM IN FREESPOOL WHEN THERE

IS A LOAD ON THE WIRE ROPE.

FORCING THE DRUM INTO

FREESPOOL WITH A LOAD ON THE

ROPE MAY RESULT IN PERSONAL

INJURY AND/OR PROPERTY DAM-

AGE. ALWAYS CHECK THAT ANY

LOAD IS SECURED BY OTHER MEANS

BEFORE ATTEMPTING TO PLACE

THE DRUM INTO FREESPOOL.

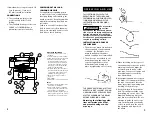

THE MANUAL FREESPOOL

MECHANISM

Models: 5364, 5366, 5370,

5372, 5374, 5376

1. To place the winch in freespool,

first remove any load from the

wire rope and drum. Grasp the

freespool handle, pull the trigger,

and lift until the latch mechanism

engages into the up position. The

wire rope may now be pulled

from the drum.

2. To re-engage the winch’s drive,

grasp the freespool handle, pull

the trigger, and lower the handle.

If the handle does not go all the

way down, do not force it. This

means the splined shaft is not

lined up for proper engagement.

Use the directional control valve

to power the winch enough to

just move the drum. The splined

shaft should snap into place, and

the handle will drop into its

down position.

DISENGAGE

ENGAGE

10

PNEUMATIC FREESPOOL

Models: 5365, 5367, 5371,

5373, 5375, 5377

The supply line to the pneumatic

freespool should be maintained

between 40 psi and 80 psi, and

should be lubricated to prevent

rusting the internal parts. The con-

nection to the winch is made to the

SAE #4 port shown in the mounting

specifications of this manual.

The control valve can be manually

or electrically operated, but must be

protected against unintentional

operation (interlocked).

Disengaging and reengaging of the

drum is accomplished by operation

of the pneumatic control valve.

When reengaging the drum, the

mechanism will spring return but

the drum will not engage until the

gears have been rotated slightly.

The freespool

must be fully

engaged before winching. If it is

not fully engaged, the winch may

run erratically, slip, and/or drop the

load entirely.

NOTE

: If the disengaging mecha-

nism does not disengage easily, do

not force it. Recheck to make sure

there is not a load on winch.

Forcing the mechanism could be

dangerous if a load is released, and

the winch could be damaged.

11