2-9

Chapter 2: Chassis Description and Installation Instructions

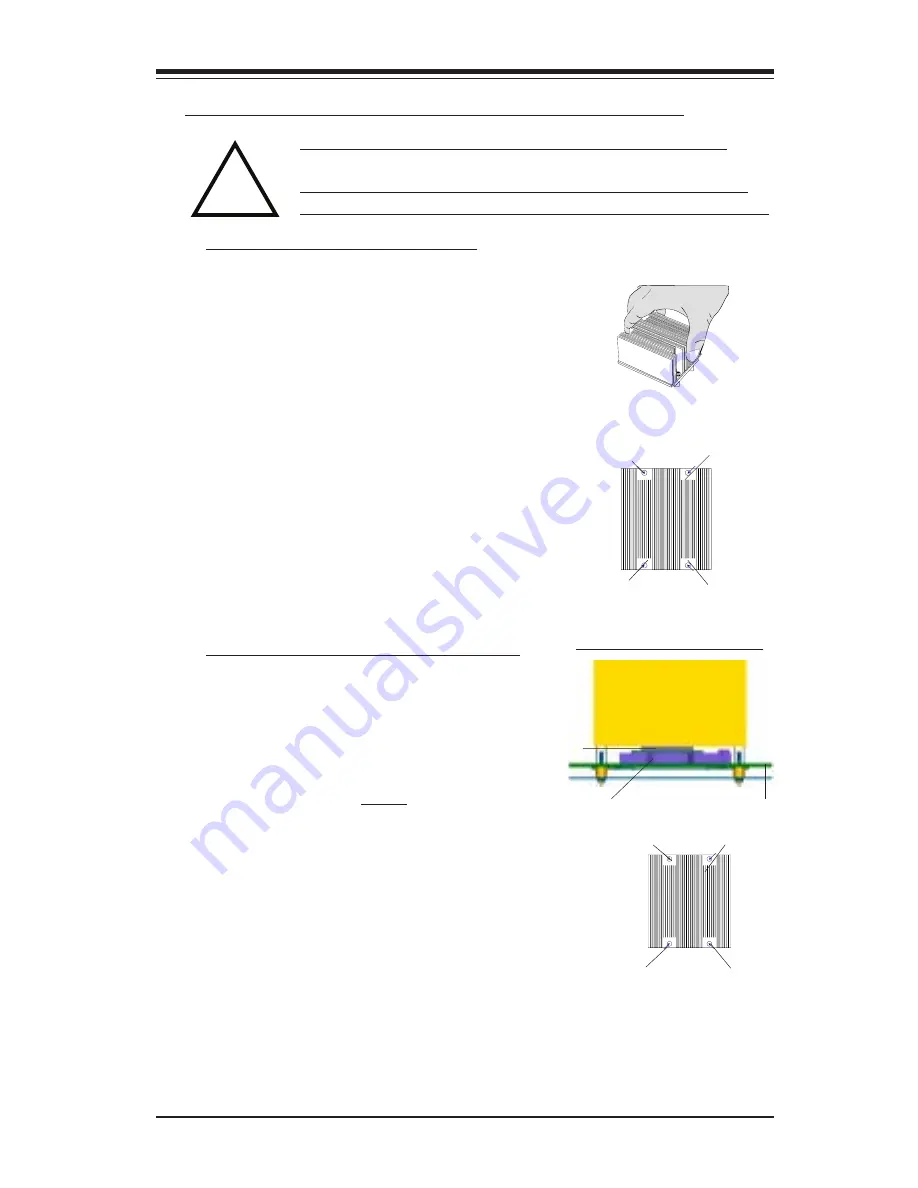

F. Installing and Un-installing the Heatsink Mechanism

1. Do not apply any thermal grease to the

heatsink or the CPU die; the required amount of

thermal grease has already been applied.

2. Place the heatsink on top of the CPU so that

the four mounting holes are aligned with those on

the retention mechanism.

3. Screw in two diagonal screws (ie the #1 and

the #2 screws) until just snug (-do not fully

tighten the screws to avoid possible damage to

the CPU.)

4. Finish the installation by fully tightening all

four screws.

Procedures: Heatsink Installation

Heatsinks are heavy. Please handle with care!!

*Note: Be sure to use Heatsink (# SNK-P0011) for a UP

system, and use Heatsink (#SNK-P0007) for a DP System.

Screw #1

Screw #2

Screw #3

Screw #4

1. Unscrew and remove the heatsink screws

from the motherboard in the sequence as

show

in the fourth picture on the right.

2. Hold the heatsink as show

in the first

picture on the right and gently wiggle the

heatsink to loosen it from the CPU. (Do not

use excessive force when wiggling the

heatsink!!)

3. Once the CPU is loosened from the

heatsink, remove the heatsink from the CPU

socket.

4. Clean the surface of the CPU and the

heatsink to get rid of the old thermal grease.

Reapply the proper amount of thermal grease

on the surface before you re-install the CPU

and the heatsink.

Procedures: Un-installing the Heatsink

Motherboard

Heatsink

CPU Socket

MB w/Heatsink installed

CPU

Screw #1

Screw #2

Screw #3

Screw #4

!