15

OPERATING THE 19-38 DRUM SANDER

Your sander will be able to perform an infinite variety of sanding projects all designed to your specifications. With

some time and experimentation the proper setting and technique for each job will become apparent.

DRUM DEPTH OF CUT

Determining the depth of cut is the most important operating procedure decision. It may take some experimen

-

tation to determine the proper depth of cut. The crucial variables to keep in mind are abrasive grit, type of wood,

project type, and conveyor feed rate. We recommend practicing on a scrap of wood prior to sanding a project.

•

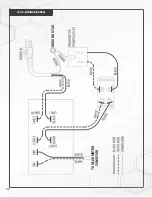

Depth Scale Operation

The depth scale (see opposite picture) measures the

distance between the conveyor table and the bottom

of the sanding drum. The sanding head must be pa-

rallel to the conveyor bed surface.

1.

To calibrate the depth scale, loosen the two screws

holding the scale. Lower the drum (with abrasive

installed) until the drum touches the conveyor belt.

2.

Slide the scale to align with the pointer at the “0”

mark. Tighten the two screws holding the scale.

An optional DRO (digital read out) for depth is avai-

lable (see opposite picture). This offers the most pre-

cise reading of sanded thickness and allows for accu-

rate repeatability of a thickness. Great when making

parts that must be an exact thickness or when matching a thickness.

1.

To operate, turn ON and select standard inch “in” or metric millimeter “mm”.

2.

Lower drum, with abrasive installed, until it touches the conveyor belt. Press “zero” button to calibrate.

•

Using Thickness Gauge

Another method to set depth of cut is to use the

thickness gauge attached to the inboard (right) side

of the sander (see opposite picture). The gauge must

be adjusted to the same height as the abrasive in use.

1.

Place a flat piece of scrap stock under the drum

with the abrasive in place. Lower the durm until the

abrasive lightly touches the scrap piece of stock.

2.

Without changing the height, place the scrap stock

under the thickness gauge. Adjust the bottom of

the gauge by loosening the large nut and rotating

the gauge up or down until it lightly touches the

scrap piece of stock.

3.

Tighten the large nut. Now the stock can be placed under the thickness gauge and the drum lowered until the

gauge lightly touches the stock to be sanded. By using this method the stock does not need to be carried under

the drum to set depth of cut.

A good rule of thumb when sanding is to place the stock under the drum and lower the sanding head until

the stock is in contact with the drum but the drum can still be rotated by hand. Normally as the depth of cut is

adjusted the handle will be rotated no more than a third of a turn at any time. INTELLISAND will help with this

process.