18

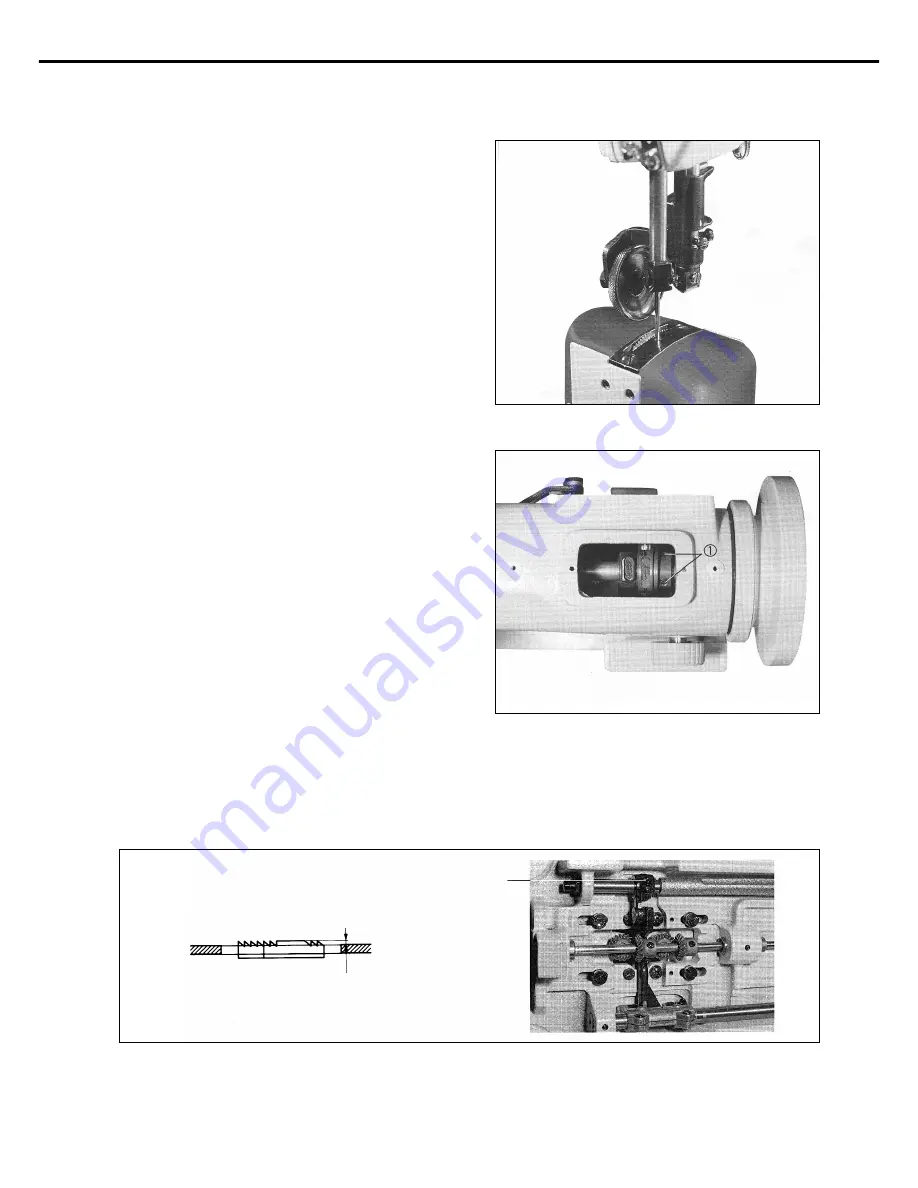

9) Adjusting timing of needle and feed dog

As in the figure, it is normal that the upper part of feed dog

goes down and the needle hole meets the upper part of needle

plate. If not, loosen the feed cam screws

①

and move the cam

position right and left to the proper match. If gear moves faster

than needle, turn the feed cam to the opposite direction of the

machine rotation. If t gear moves slower than needle, rotate to

the proper match.

[Figure 19]

[Figure 20]

10) Adjusting height of feed dog

The normal adjustment is as follows. Turn pulley to place feed dog at the height point. And loosen lifter crank clamp screw

①

to

move the crank up and down. After that, make the crank protrude 1mm in parallel with the upper needle plate and fix the gear.

[Figure 21]

①

About 1mm