Sunpak® Infrared Heaters

8

WARNING

Suspension Hazard

Mounting kits and hanging supports must

be able to withstand a minimum working

load of 75 lbs. (33 kg). Failure of the

supports can result in death.

Local codes regarding head clearance

requirement must be observed.

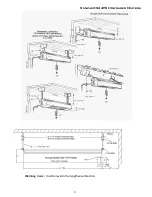

Heater Mounting and Support

Heaters shall be mounted in a fixed position independent

of gas and electrical supply line. Hangers and brackets

shall be of noncombustible material.

Heaters subject to vibration shall be provided with

vibration isolating hangers.

Suitable materials for hanging infrared heaters are steel

pipe, steel channel, or fabricated hangers of at least 16-

gage material. Hanger and brackets must be secured with

adequate anchor to a secure structure using good building

practices. Additional bracing to protect against seismic

forces may be required in seismically active areas. Never

mount heaters to a moving object such as a trailer, motor

home, boat, etc.

Gas Piping

1. A minimum pipe size of ½” is required for inlet

piping. A ½” lever handled gas shut-off valve

should be installed within 6 feet of the appliance

for servicing and as emergency shutoff to the unit.

2. Check with local and state plumbing and heating

codes regarding sizing of gas lines.

3. All gas pipe connections to the heater(s) must be

sealed with a gas pipe compound resistant to

liquefied petroleum gases.

4. Installation of a drip leg or sediment trap in the gas

supply line going to each heater is required to

minimize the possibility of any loose scale or dirt

within the gas supply line from entering the

heater’s control system.

5. When checking for gas leaks, do not use an open

flame. Use a soap and water solution.

6. For gas supply line pressures in excess of ½ PSI,

consult the factory or your local representative.

7.

Installation of 1/8” N.P.T. plugged tap accessible

for test gage connections is required upstream of

the gas supply connections to the heater.

8.

Never use pipe sealing compound on brass to

brass flared fittings.

Electrical

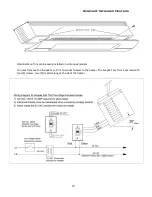

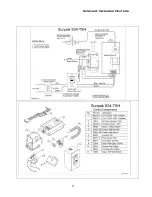

1. Sunpak S34-TSH Heaters need 24 VAC to operate.

A special lighted switch is provided which also

requires 24 VAC. In sizing your step down

120V/24V transformer always allow for a current

draw of 20 VA per heater. A 24V – 40VA

transformer will operate two heaters.

2. If any of the original wire supplied

inside

the

appliance must be replaced, it must be replaced with

wiring material having a temperature rating of at

least 105 degrees Centigrade.