Mystic Tan Kyss™

Owner’s Manual

38

T4. Sump Not Draining

You may become aware of the sump not draining by several different methods. Faults 209 and

210 will provide messages regarding the sump basin not being emptied (see Appendix 1 for a

complete list of Faults), or you may happen to notice liquid not draining after a rinse or after

cleaning the booth.

T5. Adjusting the Air Pressure

There are two main reasons you may notice a deviation in the recommended compressor PSI:

inefficient tanning results from too much or too little air pressure or from performing regular

maintenance and inspections of your unit. In either regard, proceed to the Technical > Diagnostic

Outputs page and enter your Technical screen password.

Solution 2:

If the rinse does not start after ensuring the door is closed, check the Home screen for messages (Blue

Settings gear icon on Home screen indicates a message). If a message is identified, take any necessary action, and try

again. If the problem persists after addressing any existing messages, check the Technical > Diagnostic Inputs page,

enter the Technical password, and check the values for the “Drain Float” and “Emergency Float”. If either is high,

try to manually drain the sump using the Staff > Tools page and selecting drain. If this fails to empty the drain, see

section T4. Sump Not Draining.

Solution 1:

Make sure the cutoff vale to the sewer is open to allow water to exit the sump. If the cutoff to the sewer

is closed, the sump pump will not be able to remove any water. Open the cutoff, and try to drain once more. You can

manually activate the drain from the Staff > Tools page. You can also check the current state of the sump floats from

the Technical > Diagnostic Inputs page. The technical page will require a password.

Solution 2:

If the sump is still not operating correctly, navigate to the Technical > Diagnostic Outputs, enter the

Technical screen password, and manually activate the drain. You will be able to see if the drain activates here. If

there is no change, there may be an obstruction blocking the sump basin or the hose. Close the cutoff valve and

unhook the hose from the sewer outlet first. Lower the hose or pour a small cup of water into the hose and see if the

water will flow. If the water flows, there may be an obstruction in the sump basin. Material may have fallen from a

booth user and accumulated into the sump basin. Failing to perform maintenance at the regularly scheduled intervals

may also lead to clogging. Follow the steps shown on

page 32

for “Clean the Pump Switch Plate and Sump Basin”

and follow the instructions. Remove any debris or obstructions found in the sump basin.

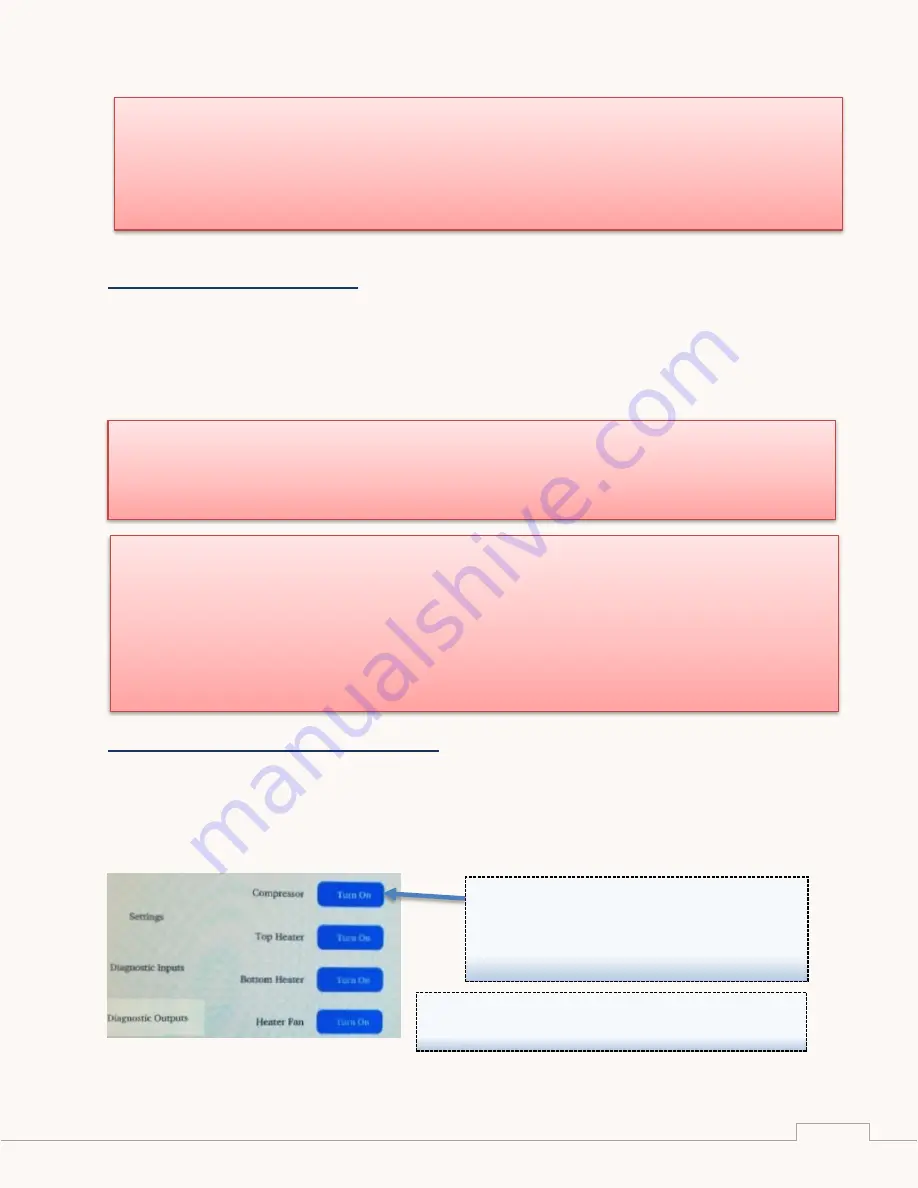

Press the Turn On button for the compressor and

check the specs displayed to the right. The PSI value

is ideally 19.5 PSI, but in the range of 18.5 to 20.5 is

acceptable. See Appendix 2 for more on tolerances.

If the compressor PSI deviates from the specified tolerance,

the bleed-off valve will need to be adjusted accordingly.