6

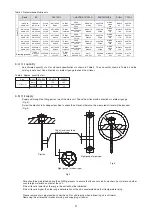

Table 4 Recommended lubricants

6-4) Oil quantity

6-5) Oil supply

An estimated quantity of oil for standard specifications is shown in Table 5. The oil quantity shown in Table 5 and the

catalog is not exact. Use a dipstick or visible oil gauge to check the oil level.

Size

Units

liters

gal(US)

SPA060

SPA070

SPA080

Oil Quantity

75

120

165

20

32

44

Table 5 Approx. quantity of oil

Brand

BP

SHELL

TOTAL

ISO VG68

AGMA 2EP

ENERGOL

GR-XP-68

ALPHA

SP68

OPTIGEAR

BM68

TRIBOL

1100/68

GEAR

COMPOUNDS

EP68

MEROPA

WM68

SPARTAN

EP68

MOBIL-

GEAR

626

OMALA

68

CARTER

EP68

ISO VG100

AGMA 3EP

ENERGOL

GR-XP-100

ALPHA

SP100

OPTIGEAR

BM100

TRIBOL

1100/100

GEAR

COMPOUNDS

EP100

MEROPA

WM100

SPARTAN

EP100

MOBIL-

GEAR

627

OMALA

100

CARTER

EP100

ISO VG150

AGMA 4EP

ENERGOL

GR-XP-150

ALPHA

SP150

OPTIGEAR

BM150

TRIBOL

1100/150

GEAR

COMPOUNDS

EP150

MEROPA

WM150

SPARTAN

EP150

MOBIL-

GEAR

629

OMALA

150

CARTER

EP150

ISO VG220

AGMA 5EP

ENERGOL

GR-XP-220

ALPHA

SP220

OPTIGEAR

BM220

TRIBOL

1100/220

GEAR

COMPOUNDS

EP220

MEROPA

WM220

SPARTAN

EP220

MOBIL-

GEAR

630

OMALA

220

CARTER

EP220

ISO VG320

AGMA 6EP

ENERGOL

GR-XP-320

ALPHA

SP320

OPTIGEAR

BM320

TRIBOL

1100/320

GEAR

COMPOUNDS

EP320

MEROPA

WM320

SPARTAN

EP320

MOBIL-

GEAR

632

OMALA

320

CARTER

EP320

ENER-

GREASE

LS EP2

SPHEEROL

AP3

Olista Long-

time 3EP

TRIBOL

3020/

1000-2

DURALITH

GREASE 68

MULTI-

FAK EP2

BEACON

EP2

MOBILUX

EP2

ALVANIA

EP2

MULTIS

EP2

EXXON MOBIL

G

ear

O

il

Bearing grease

CASTROL

CHEVRON TEXACO

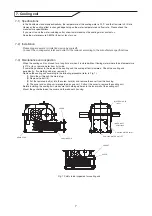

Please remove drain plug located under the unit for oil draining when lubricating oil is still warm.

Removing the air breather makes draining and supplying oil easier.

Supply oil through the filling port on top of the main unit. Check the oil level with a dipstick or visible oil gauge

(Fig.5).

Screw the dipstick to its deepest position to check the oil level; otherwise, the measured oil level will be incorrect

(Fig.6).

Care should be maintained during the oil-filling process to ensure that loose nuts, bolts, washers, dust, water and other

such foreign material do not enter the unit.

If the oil level is lower than the range, the unit will not be lubricated.

If the oil level is higher than the range, deterioration of the oil is accelerated due to oil temperature rising.

The oil level should be

within this range

Fig.5

Fig.6

Dipstick

Sight gauge (pipe type)

Sight gauge (window type)

Summary of Contents for PARAMAX SPA Series

Page 14: ......