SECTION 5

300HH, 375, 375H, 375HH, 425 AND 425H USER MANUAL R00

69

F

IRST

AND

S

ECOND

S

TAGE

D

ISCHARGE

A

IR

F

ILTER

M

AINTENANCE

—A

FTERCOOLED

&

F

ILTERED

M

ODELS

G

ENERAL

Refer to

. Familiarity with the filtration

process and the unit’s monitoring system (consisting

of a compete set of gauges) will enable the operator

to locate and analyze malfunctions.

The first and second stage filter element should be

changed when the pressure drop reaches the red

band on the pressure differential gauge.

D

AILY

O

PERATION

Check the automatic drain trap daily to ensure it is

operating properly.

F

IRST

AND

S

ECOND

S

TAGE

E

LEMENT

R

EPLACEMENT

1. Depressurize the filter and remove the filter

housing.

2. Remove the element.

3. Clean the inside of the filter housing, if nec-

essary.

4. Install a new element and gaskets

(P/N 02250153-294 FIRST STAGE)

(P/N 02250153-305 SECOND STAGE)

5. Reassemble the unit and check for air leaks.

6. Record the initial pressure drop when the

compressor is started.

S

AFETY

T

OXIC

A

ND

I

RRITATING

S

UBSTANCES

DO NOT use air from this filter as a source for

respiration (breathing air) except when in compliance

with OSHA STANDARDS 29 CFR 1910, and all other

applicable Federal, state, or local codes or

regulations.

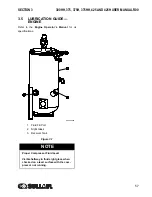

1. O-Ring

2. Filter Element

3. Filter Housing

Figure 5-7: First and Second Stage Discharge Air

Filter (Optional)

These filters will not remove water vapor, oil vapor,

carbon monoxide, or other toxic gases.

The first stage filter efficiently removes contaminants

such as ash, dust, water aerosols, lubricant mist,

carbon particles, rust and other contaminants (0.3

microns and larger).

The second stage filter removes particulates and all

lubricant aerosols of 0.01 micron size and larger.

D

ESIGN

R

ATINGS

Design ratings are 150°F (66°C) maximum air inlet

temperature. All welded filter housings are code

stamped for 250 psig (17.3 bar) maximum working

pressure.

WARNING

Death or serious injury can result from

inhaling compressed air without using

proper safety equipment. (See applicable

OSHA Standards)

1

1

2

3

SU_0000680

Summary of Contents for 300HH

Page 17: ...SECTION 1 15 Safety Symbols 2 ...

Page 18: ...SECTION 1 16 Safety Symbols 3 ...

Page 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Page 60: ...NOTES 58 ...

Page 79: ...NOTES ...