Section 1

1600H T4F CAT/Perkins Addendum

1: Description

02250251-632 R01

Subject to EAR, ECCN EAR99 and related export control restrictions.

5

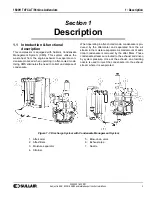

Description

1.1

Introduction & functional

description

This compressor is equipped with Sullair’s Condensate

Management System (CMS). This system utilizes the

waste heat from the engine exhaust to evaporate con-

densate produced when operating in after-cooled mode.

Using CMS eliminates the need to collect and dispose of

condensate.

When operating in after-cooled mode, condensate is pro-

duced by the aftercooler and separated from the air

stream in the moisture separator. A small amount of addi-

tional condensate is removed by the after filters. These

condensate streams are routed to the exhaust and driven

by system pressure. Once at the exhaust, an atomizing

nozzle is used to inject the condensate into the exhaust

stream where it is evaporated.

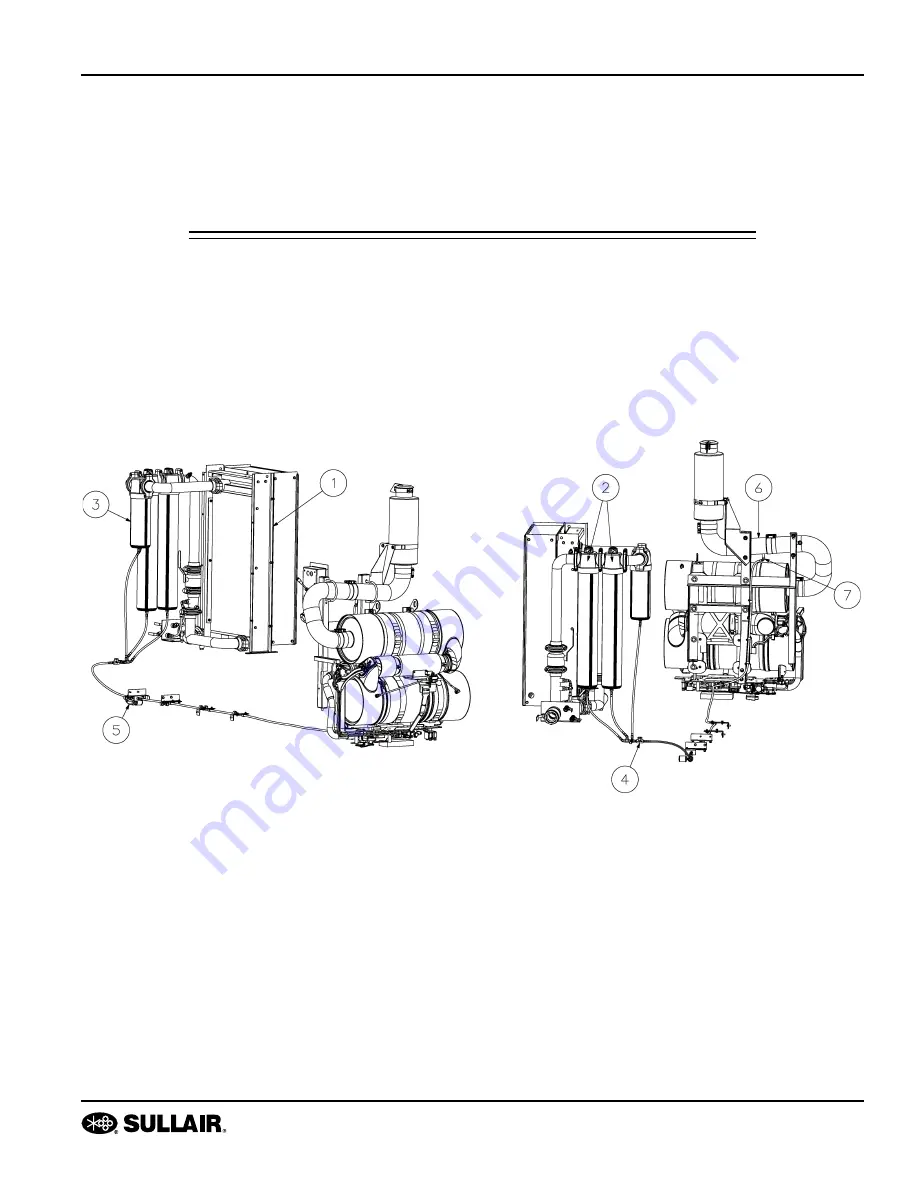

Figure 1-1: Discharge System with Condensate Management System

1.

Aftercooler

2.

After-filters

3.

Moisture separator

4.

Strainer

5.

Blow-down valve

6.

Exhaust pipe

7.

Nozzle