DE-STA-CO

Subject to technical modifications without notice

15.13

S

tr

o

n

g

H

o

ld

C

la

m

p

in

g

S

y

s

te

m

T

M

Example: Boring a hole in alloy steel heat treated to 37 Rc (unit power

1.7), with a depth of cut of .060", a feed rate of .003" inches per

revolution gives a result of:

.060 x .003 X 1.7 x 396,000 = 121 lbs. Cutting Force

Drilling

The forces involved in drilling can be separated into two distinctly

different categories: thrust and torque. With the number of drill styles

available, the thrust varies tremendously. Torque is somewhat less

variable and can be estimated as shown:

Feed (IPR) x (Drill Dia.)

2

x Unit Power x 49,500 =

Drilling Torque (In. Lbs.)

For example, drilling a 3⁄4” diameter hole in magnesium (unit power .2)

with a feed rate of .010” per revolution gives a result of:

.010 x .75

2

x .2 x 49,500 = 56 in. lbs.

Friction Coefficient

Now that an estimate of the amount of cutter force being transferred to

the workpiece is available, we must determine how much clamping

force is necessary to resist the cutter force. This depends on the

amount of friction between the workpiece and the fixture, commonly

referred to as the friction coefficient.

Typically, if an object is lying on a surface, the amount of force required

to slide it sideways will be considerably less than the weight of the

object. It follows then that when clamping a workpiece to resist

machining forces, the clamping force will need to be much higher than

the machining force. The following chart shows approximate

friction coefficients:

The estimated clamping force is divided by the appropriate friction

coefficient and then multiplied by a suitable safety factor to get an

estimated total clamping force required.

Example: A steel workpiece on steel rest buttons is being machined

using coolant. The estimated machining force is 300 lbs. From the table

the friction coefficient for steel on steel (lubricated) is .16. After

choosing an appropriate safety factor (usually about 2), the estimated

total clamping force would be:

This total clamping

force may now be

divided

by

the

number of clamps

holding

the

workpiece, which

equals the clamping

force needed for

each clamp.

Depth of Cut (in.)

Feed per Revolution (in.)

Unit Power

____X____X____X 396,000 = _____ lbs.

Cutting Force

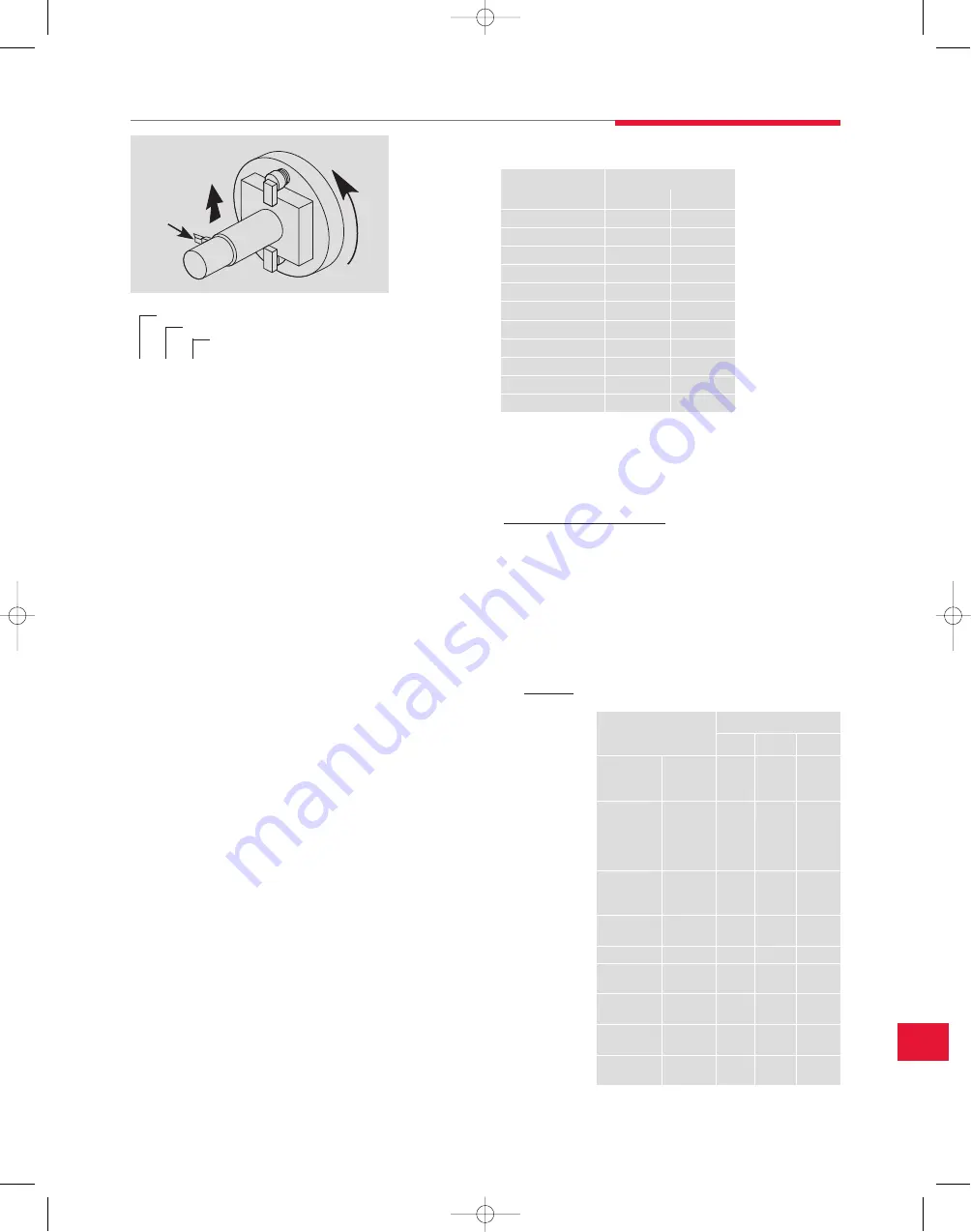

Force

Cutting

Tool

Static Friction Coefficients

for Steel on Various Materials

Machining Force (lbs.)

Friction Coefficient

x Safety Factor = Total

Clamping

Force (Lbs.)

300

.16

x 2 = 3750 lbs. Total Clamping Forces

System design information

TABLE A

Unit Power hp/in

3

/min

Turning

Drilling

Milling

Material

Hardness

Bhn

HSS &

Carbide

Tools

HSS

Drills

HSS &

Carbide

Tools

STEELS

Plain

Carbon

Alloy Steels

85-200

35-40Rc

40-50Rc

50-55Rc

55-58Rc

1.4

1.7

1.9

2.5

4.2

1.3

1.7

2.1

2.6

3.2

1.4

1.9

2.2

2.6

3.2

CAST IRONS

Gray, Ductile

& Malleable

110-190

190-320

0.9

1.7

1.2

2.0

0.8

1.4

STAINLESS

STEELS

135-275

30-45Rc

1.6

1.7

1.4

1.5

1.7

1.9

TITANIUM

250-375

1.5

1.4

1.4

NICKEL

ALLOYS

80-360

2.5

2.2

2.4

ALUMINUM

ALLOYS

30-150

500 kg

0.3

0.2

0.4

MAGNESIUM

ALLOYS

40-90

500 kg

0.2

0.2

0.2

COPPER

ALLOYS

10-80Rb

80-100Rb

0.8

1.2

0.6

1.0

0.8

1.2

Material

Friction Coefficient

Clean

Lubricated

Brass

0.35

0.19

Bronze

–

0.16

Bronze, Aluminum

0.45

–

Bronze, Phosphor

0.35

–

Bronze, Sintered

–

0.13

Carbon, Hard

0.14

0.11-0.14

Copper-Lead Alloy

0.22

–

Graphite

0.10

0.10

Iron, Cast

0.40

0.21

Steel

0.80

0.16

Tungsten Carbide

0.4-0.6

0.1-0.2

15_StrongHold.qxp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.13