DE-STA-CO

Subject to technical modifications without notice

15.11

S

tr

o

n

g

H

o

ld

C

la

m

p

in

g

S

y

s

te

m

T

M

Torque vs. Tension

A user’s first introduction to hydraulic power workholding is often

the replacement of the nut on a typical strap clamp with a center

hole cylinder.

If the torque of the nut is known, the resulting tension on the bolt or

stud can be easily approximated.

For example, a 1⁄2-13 UNC nut is torqued to 300-in. lbs. The resulting

approximate tension would be:

The most accurate way to determine that the hydraulic power clamping

system is exactly duplicating the mechanical system is to place the

center hole cylinder over the stud or bolt and replace the nut loosely

over the cylinder. Use the hydraulic system to partially extend the

cylinder until it contacts the nut. Use a torque wrench to torque the nut

to its original value while monitoring the system pressure gauge. When

the nut is properly torqued, the gauge will indicate the exact system

pressure setting for this application.

Operating Pressures

Most DE-STA-CO workholding components are rated at 5,000 PSI.

When designing, it is a good rule of thumb to choose components for

your fixture that will give you the forces you need at a pressure of about

3,000 PSI. This gives you plenty of latitude to adjust the system

pressure both up and down when fine tuning the fixture on the machine

tool. Operating at lower pressures, while sometimes necessary, does

not make the most efficient use of these components. Higher pressures

allow the use of smaller components, saving cost and fixture space.

Design Stroke Length

Clamps and cylinders should never be designed into a fixture at their

rated full stroke. Always use something less than full stroke to make

sure that all tolerances and variations in the workpiece, workholding

device and fixture can be accepted, insuring that the workpiece is

properly clamped.

Volume Calculations

The total volume required to actuate a circuit should be checked to

make sure that the power source chosen has enough usable fluid

capacity. The fluid volume required to fully actuate each clamp and

cylinder is listed in the charts on each product page throughout the

catalog. By totaling this value for each component, you know the

maximum fluid volume that could possibly be used in this fixture. Even

the smallest DE-STA-CO pumps have enough fluid volume for most

applications.

Since the fixture is designed to use less than the full stroke of the

actuators, the actual fluid volume will be less. If it becomes necessary

to get an exact figure, it can be easily calculated using the

following formula:

Effective Area (sq. in.) X Stroke (in.)

= Fluid Capacity (cu. in.)

The effective area of the actuators (from product chart) multiplied by

the stroke used (not total stroke) will result in the fluid volume.

For example, if a cylinder has an effective area of 2 square inches, and

an actual stroke of 3 inches, its fluid volume will be 2 x 3 or 6 cubic

inches. (For easy reference, 231 cubic inches = 1 gallon.)

System Care and Maintenance

The single most important factor in determining the life of a properly

designed system is the effort taken to keep the fluid clean.

System Flushing

During assembly, make sure all fluid-carrying components are flushed

with clean solvent and blown dry. Hydraulic tubing is particularly

notorious for the amount of contaminants found inside. If not removed,

this debris will quickly damage seals and score precision-fit metal

parts. The contamination will also clog passages in pumps and

control valves.

After fixture assembly, the entire system should be flushed to remove

any contamination created during assembly. Use only hydraulic fluid for

this procedure. Solvents may become trapped in the system,

contaminating the fluid.

Once the fluid in the system is clean, be sure to keep it that way by

changing the fluid on a regular basis and making sure that extreme

care is taken whenever the system is disconnected or disassembled so

that new contaminants are not introduced.

Torque (In. Lbs.)

Nominal thd. size (In.) X .12

= Tension (Lbs.)

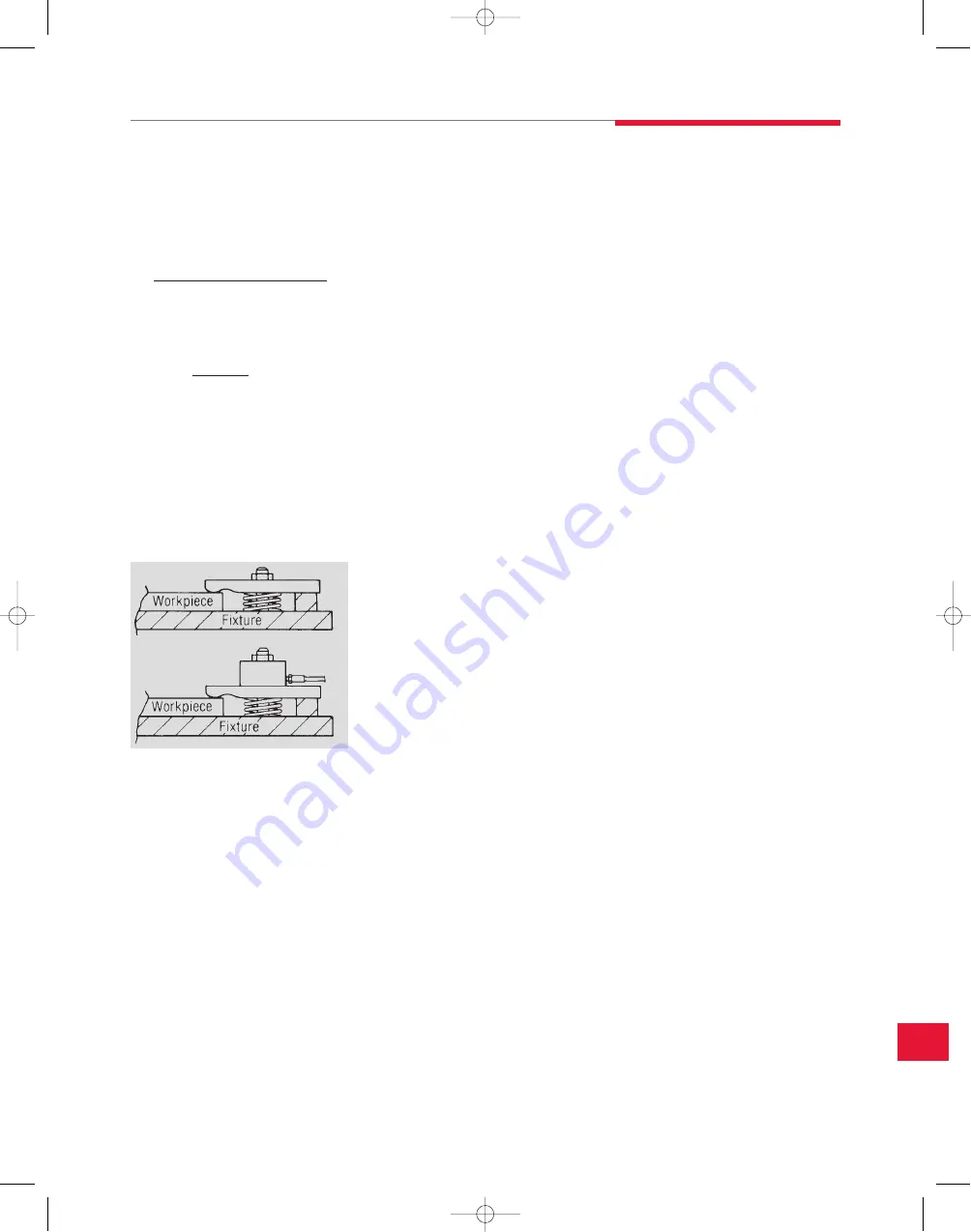

From this:

To this:

= 5,000 lbs. Tension

300

.5 x .12

System design information

15_StrongHold.qxp:15_DES_StrongHold-1-14.indd 1/2/08 9:03 AM Page 15.11