RECEIVING & INSTALLATION

THE PRO-35 PROJECTOR is shipped in a sturdy wooden crate to minimize the possibility of

damage in shipment. Remove first the top of the crate (as marked). Identify the operators side of the projector

and remove that side of the crate. The projector is secured to the crate with (2) 3/8-16 screws threaded into the

projector base casting, and (2) 3/8-16 bolts with hex nuts. Remove all (4) of these fasteners. Inspect the

projector and report any damage to the freight carrier immediately. It is the responsibility of the consignee, not

the shipper, to initiate damage claims.

IF INSTALLING a Pro-35 to a VIP Base, the Model VII soundhead is factory-mounted to the

base; otherwise, the soundhead must be mounted to a pedestal or projection console. Three holes, on the top

surface of the Model VII main frame casting are tapped 3/8-16 and align with (3) clearance holes in the bottom

casting of the Pro-35. Mount the projector to the soundhead and secure using the (3) 3/8-16 socket head screws

provided. The locations of these clearance holes are held to a close tolerance, and no further projector-to-

soundhead alignment is required.

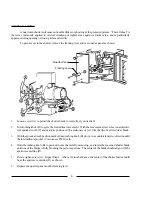

INSTALL THE INTERMITTENT

FLYWHEEL and pulley assembly to the intermittent cam-

shaft as illustrated. Observe the assembly sequence of

the components.

Do not add oil to the projector until

first installing and securing the intermittent flywheel.

INSERT THE PLASTIC FUNNEL into

the oil fill cup on the top of the projector and add Ballantyne

Projector Oil until the oil level reaches the ring on the oil

fill hose. While adding the oil, periodically rotate the in-

termittent flywheel to turn the mechanism and eliminate

air locks. DO NOT OVERFILL.

AN ALTERNATE METHOD of adding

the projector oil is to remove the breather tube from the

top of the projector and prop open the oil fill cup. Insert

the funnel into the breather tube opening and add the oil,

while periodically rotating the intermittent flywheel as

above. After filling, replace the breather tube and reset

the lid of the oil cup.

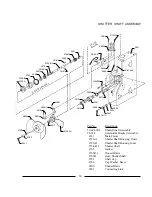

INSTALL THE DRIVE BELT between the motor pulley and the intermittnet flywheel pulley.

The standard 115 V.AC induction motor is mounted to the base casting of the projector in a pivoting support

cradle. Apply belt tension by tightening the front-mounted socket head screw connected to the motor cradle

until belt tension is adequate.

THE SYNCHRONOUS DRIVE MOTOR mounts to the top casting of the projector. Run the

drive belt from the motor pulley to the intermittent flywheel pulley and apply belt tension by tighening the idler

roller mounted to the inside of the top casting against the drive belt.

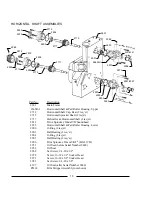

3041 Screw

2783 Cap

2786-D Washer

Intermittent Movement

P8014 Flywheel & Pulley

Oil Level Ring

(Do Not Overfill)

2943 Oil Fill Hose

2

Summary of Contents for Ballantyne PRO-35

Page 15: ......