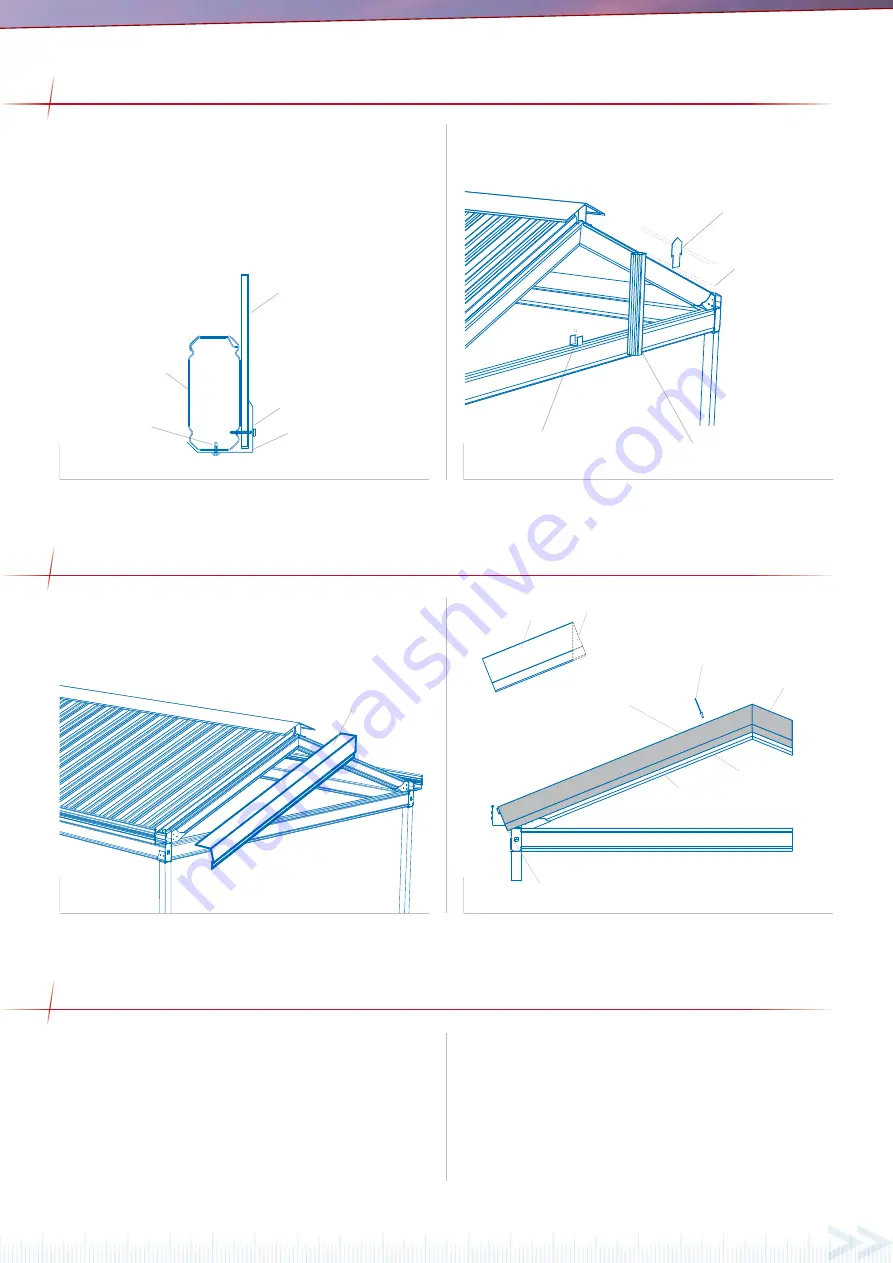

Figure 23.0

Figure 23.1

Gable infill panels are to be cut in triangle shapes to fit the end

frame. Panels can be painted to the desired colour before installing.

End struts are fixed mid-span of the header to a header beam

bracket at the base and an end strut plate at the ridge. Infill panels

are fixed through the top groove of rafters and the lower groove of

the header beam with 8x35mm self embedding self drillingt screws

at 500mm centres. Panels are fixed to the end strut at the same

spacings. Attach the header flashing to the underside of the header

beam with 12x20 hex head screws to neatly finish the base of the

infill panels. Refer figure 23.0 and 23.1.

infill panel

8x35 self embedding screws

header flashing

12 x 20 hex head

self drilling screws

header beam

fix bracket to header wiith

two 12x20 hex head self

drilling screws

fix to strut with two

12x20 hex head self

drilling screws either

side

fix to front of ridge with

two 12x20 hex head self

drilling screws

fix strut to bracket with two 12x20 hex

head self drilling screws on either sides

Fixing into the Concrete Footing

Thoroughly check the posts with a spirit level. When plumb, fill the

post hole with approximately 150mm of concrete and use a shovel

or pole to agitate the concrete to remove any air pockets. Repeat

this process until the hole is full, continually checking the posts

as you go. The concrete must have a slight slope that runs away

from the column to ensure any water does not pool around the

base (figure 25.0). Once the concrete is set remove any temporary

bracing or props.

Fixing onto Existing Concrete: External Footing

If the columns are to be fixed to an existing concrete slab with an

external footing plate, each plate must be fixed to the concrete. For

a 68 Outback Column refer figure 25.1, for a reinforced 68 Outback

column refer 25.3 and for an SHS column refer figure 25.2. The

minimum distances from an anchor hole to the concrete edge is

70mm for M10 anchors, 75mm for M12 anchors and 120mm for

M16 anchors.

FINAL FIXING

Attach the barge cap by screwing the lower lip to the gable rafter

and rivet the top section to the deck as shown in figure 24.1. Mitre

the barge at the apex of the gable for a neat finish. Trim the barge

at the gutter end to ensure a neat finish.

Figure 24.0

Figure 24.1

ATTACHING BARGE CAPPING

barge cap

barge cap

mitre end

mitred barge cap

gable rafter

mitred barge cap

fr

on

t gut

ter

gut

ter st

rap

gut

ter

riv

et

ed

to cutback

flashing and

top sheet

eiving channel

4.8mm sealed

riv

ets

rivet barge cap to crest of

decking at 500mm centres

trim barge cap

for neat finish

fix barge cap to gable rafter

at front using 12x20 hex

head self drilling screws