47

8. Conversion and repair

If you want to change the spray pattern beyond the possibilities already mentioned, the spray gun has to be refitted.

The air cap / material nozzle / needle combination suitable for a certain spray material constitute a harmonised unit -

the nozzle insert. Always replace the complete nozzle insert in order to retain the requested spray pattern quality.

WARNING:

Prior to any refitting, depressurise the air and material feed to the spray gun - risk of injury.

NOTE:

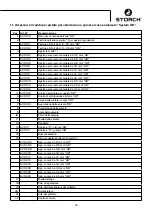

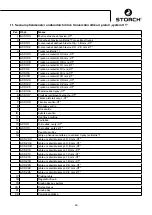

In order to carry out the procedure mentioned below, please use the exploded drawing at the end of this

operating manual.

8.1. Changing material nozzle and air cap

1. Unscrew union nut, item 1.

2. Remove the air cup, item 2.

3. Use spanner 13 to unscrew the material nozzle, item 3, from the gun body.

4. Remove the seal, item 4, from the material nozzle.

The installation of the new nozzle insert as well as the remaining component parts is carried out in reverse order.

8.2. Changing the material needle

1. Unscrew the adjusting screw, item 18.

2. Remove the spring, item 17.

3. Pull the material needle, item 16, from the gun body.

Assembly is conducted in reverse sequence. The pre-air setting is not required.

8.3. Replacing leaking needle packs

In case of packs with fastening screw:

1. Remove the material needle as described in chapter 8.2.

2. Remove the fastening screw, item 32.

3. Remove the pack, item 33, complete with O ring seal, item 34.

Assembly is conducted in reverse sequence.

NOTE:

The needle pack removed from the gun attachment must not be used again as otherwise a functionally

safe seal is not ensured.

NOTE:

Prior to installation all moveable or sliding component parts have to be greased with an acid-free resin-

free grease.