139

11. Troubleshooting

Problem

Cause

Remedy

Device does not vent

and fails to build up

pressure

Air leaking due to loose suction

valve nut

Tighten the suction valve nut

Air leaking due to worn O rings

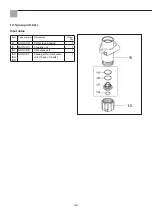

Replace the O-rings 69 03 97 on the suction valve seat

Air leaking as a result of a hole in

the suction hose

Replace the suction hose

Jammed or damaged ball valves

Maintain the inlet and outlet valves

The pump ventilates

but builds up virtually

no pressure, or insuffi-

cient pressure

Pressure set too low

Increase the pressure

Clogged filter

Clean the gun filter, the inlet filter and/or the device fil-

ter, or replace them as needed.

Discharge valve

Jammed/worn

Maintain the outlet valve

Air valve leaking

Clean or replace the air valve

Packing elements and/or piston

worn

Tighten the gland nut; replace the packing element

Device does not

maintain spraying

pressure

Worn spray nozzle

Replace the spraying nozzle.

Packing elements and/or piston

worn

Replace the packing elements and also the piston if

necessary

Upper valve seat worn

Replace the worn seat.

Pump not working

Fuse gone

Replace fuse:

220 – 240 V models: slow blow 8A fuse

The device will not

switch on

Control settings

Make sure the mains plug on the device is plugged in.

Make sure that the ON/OFF switch is set to ON positi-

on and that the pressure regulator button has been fully

turned in clockwise direction (max. pressure).

Pressure regulation unit

(controller card)

If the power display is not lit after checking the control

settings and the power source, you must replace the

pressure control unit.

Motor

Remove the cover on the motor brushes and switch

the device on. Set the pressure regulator to maximum

pressure and check the DC voltage on all the brush

connectors. The voltage should be more than 80 V DC.

If DC voltage is present, switch off the device and dis-

connect the mains plug. Make sure that the brushes are

in contact with the rotor. Replace the brushes if their

length is below 12.7 mm. If the brushes are OK, replace

the motor.

Device unexpectedly

switches off during

operation

Activate the overload switch to

prevent the motor from overhea-

ting

The device automatically restarts as soon as the over-

load switch is deactivated. Turn the ON/OFF switch to

OFF position to prevent an automatic restart. Wait 30

minutes. Restart the device.

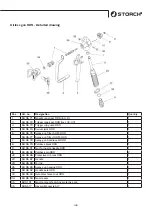

Summary of Contents for LP 400 F

Page 1: ...Airless LP 400 F DE NL FR IT GB CZ ...

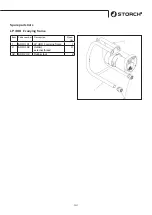

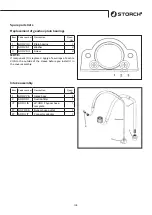

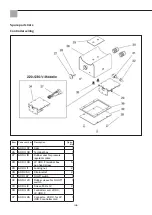

Page 22: ...22 Ersatzteillisten Motor Antrieb ...

Page 52: ...52 Motor aandrijving ...

Page 82: ...82 Nomenclatures de pièces de rechange Moteur entraînement ...

Page 112: ...112 Elenchi dei pezzi di ricambio Motore Azionamento ...

Page 142: ...142 Spare parts lists Motor gearbox ...

Page 172: ...172 Seznamy náhradních dílů Motor pohon ...

Page 182: ...182 ...

Page 183: ...183 ...