27

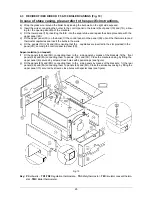

5 START UP

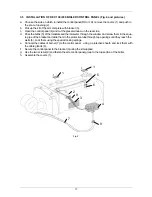

WARNING: Before start up, open the door and insert w holly turbolators into

the front end sections of the smoke tubes, ensuring that they hav e been

pushed inside for at least 100 mm.

5.1 PRELIMINARY CHECKS

Before starting the boiler, check that:

- The

rating plate

specifications and power supply network (electricity, water,

gas or fuel oil) specifications correspond;

- The burner

power range

is compatible with the power of the boiler;

- The boiler room also contains the instructions for the burner;

- The

flue gas exhaust pipe

is operating correctly;

- The

air inlet supply

is well dimensioned and free from any obstacle;

- The

manhole

, the

smokebox

and the

burner plate

are closed in order to provide a complete flue gas

seal;

- The system is

full of water

and that any

air pockets

have therefore been eliminated;

- The

anti-freeze

protections are operative;

- The water

circulation pumps

are operating correctly.

- The expansion vessel and the safety valve(s) hav e been connected correctly (with no interception) and

are properly operating.

- Check the electrical parts and thermostat operation.

5.2 WATER TREATMENT

The most common phenomena that occur in heating systems are:

- Scaling

Scale obstructs heat transfer between the combus tion gases and the water, causing an abnormal in-

crease in the temperature of the metal and therefore reducing the life of the boiler.

Scale is found mostly at the point s where the wall temperature is highest and the best remedy, at con-

struction level, is to eliminate areas that overheat.

Scale creates an insulating layer which reduces the thermal transfer of the generator, affecting system ef-

ficiency. This means that the heat produced by burning the fuel is not fully exploited and is lost to the flue.

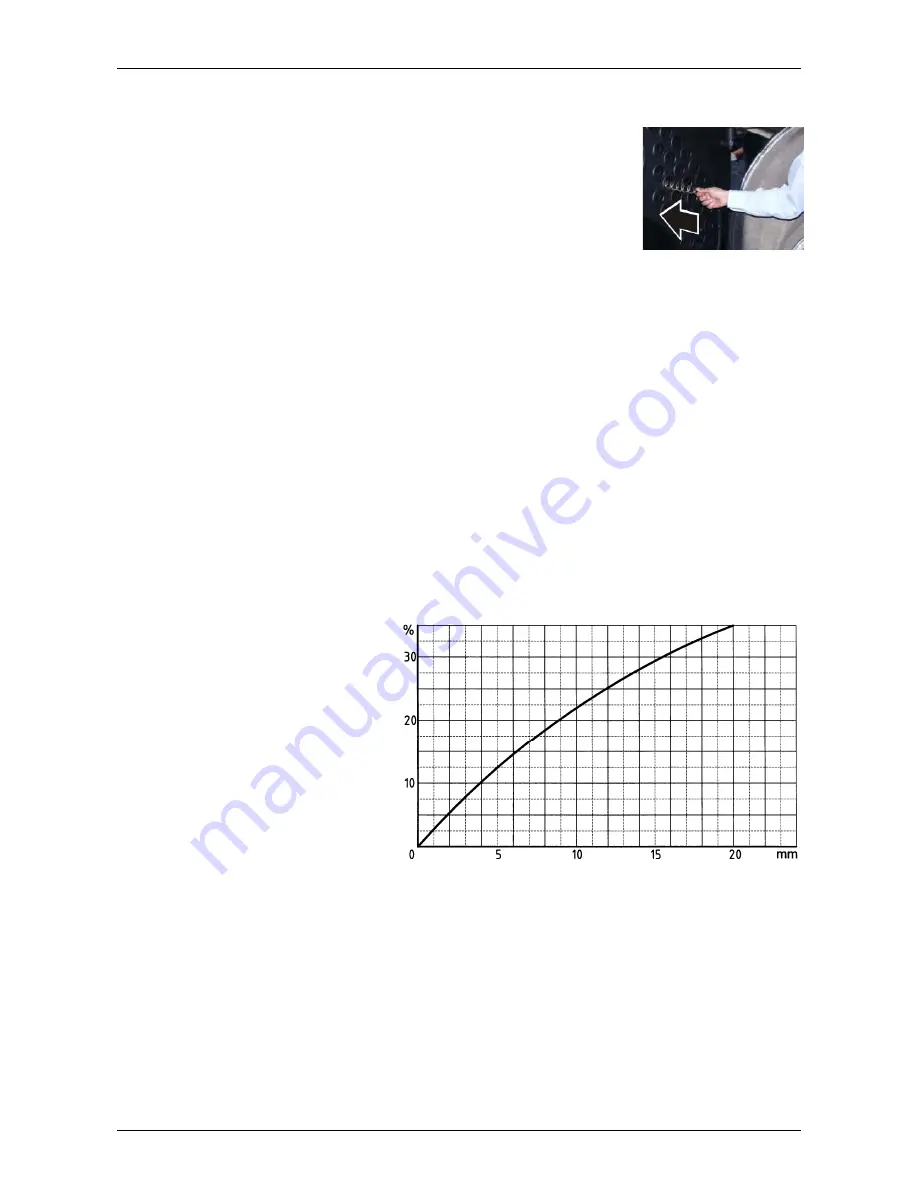

Scale diagram

Key

%

% fuel not used

mm

mm scale

- Corrosion on the water side

Corrosion of the metal surfaces of the

boiler on the water side is due to the

passage of dissolved iron through its

ions (Fe+). In this process the presence

of dissolved gases and in particular of oxygen and car bon dioxide is very important. Corrosion often oc-

curs with softened or demineralised water which has a more aggressive effect on iron (acid water with Ph

<7): in these cases, although the sy stem is protected from scaling, it is not protected against corrosion

and the water must be treated with corrosion inhibitors.

5.3 FILLING THE SYSTEM

The water must enter the system as slowly as possible and in a quantity proportional to the air bleeding

capacity of the components involved. Filling times vary depending on the capacity and characteristics of

the system but should never be less than 2 or 3 hours.

In the case of a system with closed expansion vessel, water must be let in until the pressure gauge indicator

reaches the static pressure value pre-set by the vessel.

Heat the water to maximum temperature. During this operation the air contained in the water is released

through the automatic air separators or through manual bleed valves. The water discharged from the system

with elimination of the air is made up by the automatic or manual filling valve.

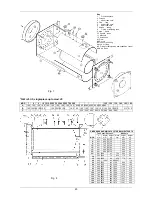

Summary of Contents for REX F

Page 1: ...TECHNICAL MANUAL REX REX F REX K REX K F REX DUAL REX DUAL F PRESSURISED STEEL BOILERS...

Page 2: ......

Page 18: ...18 1 2 6 3 4 5 9...

Page 30: ......

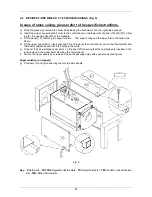

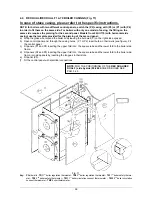

Page 32: ...ASSEMBLY INSTRUCTIONS STAVES LINING...

Page 33: ......