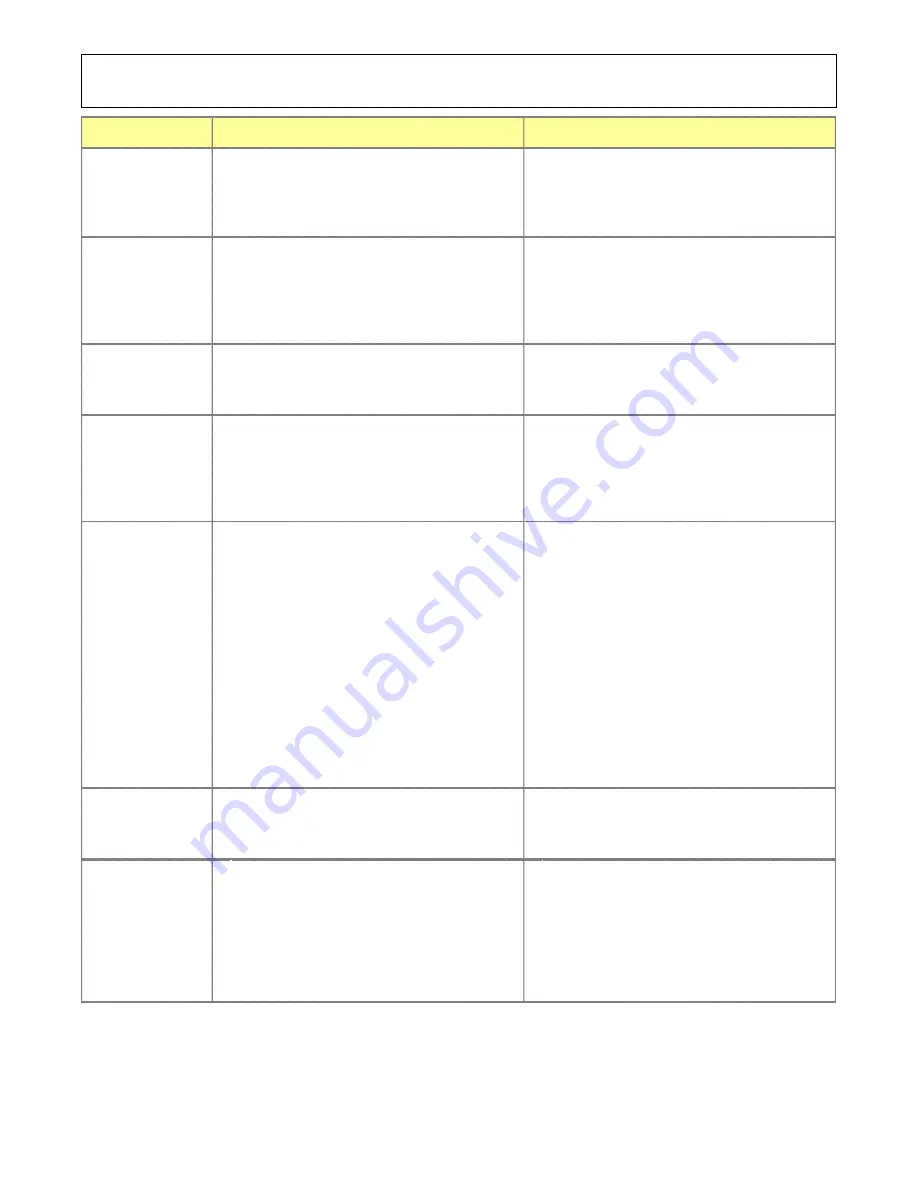

17

SECTION 4

TROUBLESHOOTING

PROBLEM

1. Power to freezer is off.

1. Supply power to freezer.

2. Fuse or circuit if blown or tripped.

2. Replace or reset.

3. Freeze-up (auger will not turn).

3. Turn Power OFF-ON switch to OFF for 15

minutes, then restart.

4. Front door not in place.

4. Assemble front door in place.

1. Freezer has been left in the CLEAN mode for

more than 20 minutes.

1. Let light flash for 10 minutes, then place the

Power OFF-ON switch to the OFF position to

reset.

2. CLEAN switch has been activated 3 times

within 10 seconds.

2. Leave Power OFF-ON switch in the ON position

for 10 minutes, then place the switch to the

OFF position to reset.

1. No mix in hopper.

1. Fill hopper with mix

2. Mix inlet regulator not allowing mix to flow into

barrel.

2. Remove mix inlet regulator, clean, sanitize, and

replace.

3. Sensor problem.

3. Call distributor for service.

1. Temperature setting is too cold.

1. Readjust. Call distributor for service.

2. Push to freeze switch failure.

2. Call distributor for service.

3. Spigot switch failure.

3. Call distributor for service.

4. Reduced air flow.

4. Check for proper air flow through the condenser

5. Refrigeration problem.

5. Check system. Call distributor for service.

1. Product is being dispensed when the PUSH TO

FREEZE light is illuminated red.

1. Press the PUSH TO FREEZE push button.

Wait until the green light illuminates before

dispensing.

2. No vent space for free flow of cooling air.

2. A minimum of 3" of vent space required.

3. Air temperature entering condenser is above

100°F.

3. Change location or direct hot air away from

freezer.

4. Condenser is dirty.

4. Clean condenser.

5. Temperature setting too warm.

5. Readjust. Call distributor for service.

6. Stabilizers in mix are broken down.

6. Remove mix, clean, sanitize and restart with

fresh mix.

7. Auger is assembled wrong.

7. Remove mix, clean, reassemble, sanitize and

restart freezer.

8. Reduced air flow.

8. Check for proper air flow through the

condenser.

9. Refrigeration problem.

9. Check system. Call distributor for service.

1. Small portions are being dispensed in a short

time.

1. Allow freezer to sit idle for 5 minutes before

dispensing.

2. Temperature setting is too cold.

2. Readjust. Call distributor for service.

3. Line voltage fluctuating.

3. Call distributor for service.

1. No mix in hopper.

1. Fill hopper with mix.

2. Mix inlet regulator tube is plugged.

2. Unplug, using small sanitized brush.

3. Special mix inlet regulator needed for mix being

used.

3. Order special mix inlet regulator.

4. Drive motor overload tripped.

4. Automatic reset. Wait 15 to 30 minutes.

5. Drive belt failure.

5. Replace drive belt.

6. Freeze-up. (Auger will not turn.)

6. Turn Power OFF-ON switch to the OFF position

for 15 minutes, then restart.

REMEDY

POSSIBLE CAUSE

Product does not

dispense.

Product is too thin.

Freezer does not

run.

Freezer will not shut

off.

Product is too thick.

Freezer does not

run, PUSH TO

FREEZE light

flashes in sequence

Freezer does not

run, PUSH TO

FREEZE light

flashes in sequence

of four.

Summary of Contents for SO212

Page 1: ...Model SO212 OPERATORS MANUAL Manual No 513610 Rev 2...

Page 2: ......

Page 12: ...6...

Page 22: ...16...

Page 28: ...22...