5

Maintenance

General maintenance information

General maintenance information

General

The following instructions contain all the

information required for servicing your truck.

Carry out the various maintenance work in

compliance with the maintenance plan. This

will ensure that your truck is reliable and in

good working order and that the warranty

remains valid.

Maintenance should only be carried out by

authorised technicians, or by authorised deal-

ers in accordance with a signed maintenance

contract.

Modifying or installing additional equipment

on the forklift truck is prohibited without the

agreement of the manufacturer.

NOTE

If the data plates or affixed labels are incom-

plete or damaged, they should be replaced

with new ones. For locations and reference

numbers, please see the spare parts catalo-

gue.

CAUTION

If the forklift truck is used in an extreme environment

(such as excessive heat, excessive cold or areas

with high dust concentrations), the time intervals

given in the maintenance tables should be reduced

accordingly.

ENVIRONMENT NOTE

Please comply with regulations regarding

the use, handling and disposal of fuel and

lubricating oil.

The forklift must undergo functional testing

and a trial run after each inspection.

Service plan

Maintenance work must be carried out accord-

ing to the maintenance checklist.

The service plan is followed by advice to

facilitate work.

Maintenance intervals must be reduced if the

truck is used under harsh conditions (extreme

heat or extreme cold, large quantities of dust).

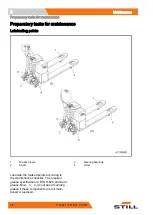

Grade and quantity of lubricants and

other consumables

Only lubricants and other consumables

specified in these operating instructions are

authorised for use during maintenance work.

Lubricants and other consumables required

for truck maintenance are listed in the mainte-

nance specifications table.

Never mix different qualities of grease or oil.

If it is absolutely necessary to change brands,

make sure to flush thoroughly beforehand.

Before changing any filters or working on

the hydraulic system, thoroughly clean the

surface and the areas around the part.

All containers used to pour oil must be clean.

Daily inspection

This chapter describes pre-shift checks before

putting the truck into operation.

Daily inspection is effective to find the mal-

function or fault on this truck. Check the truck

on the following points before operation.

Remove load from truck and lower the forks.

CAUTION

Risk of injury.

Don't use the truck if any malfunction is found.

• Check for scratches, deformation or cracks.

• Check if there is any oil leakage from the

cylinder.

54

1133 801 16 01 EN - 11/2018

Summary of Contents for ECU 15C

Page 1: ...Original instructions Electric pallet truck ECU 15C 0138 1133 801 16 01 EN 11 2018 ...

Page 2: ......

Page 8: ......

Page 9: ...1 Introduction ...

Page 23: ...Introduction 1 Residual risks 1133 801 16 01 EN 11 2018 15 ...

Page 28: ...1 Introduction Residual risks 20 1133 801 16 01 EN 11 2018 ...

Page 29: ...2 Safety ...

Page 41: ...3 General views ...

Page 45: ...4 Operation ...

Page 61: ...5 Maintenance ...

Page 70: ...5 Maintenance Trouble shooting 62 1133 801 16 01 EN 11 2018 ...

Page 71: ...6 Technical data ...

Page 77: ......