42

MS 192 T

Exercise extreme caution while

carrying out maintenance and repair

work on the ignition system. The

high voltages which occur can

cause serious or fatal accidents.

Troubleshooting on the ignition

system should always start with the

spark plug,

The electronic ignition system

basically consists of an ignition

module (1) and flywheel (2).

2

1

217RA097 TG

The ignition module accommodates

all the components required to

control ignition timing. There are

two electrical connections on the

coil body:

:

High-voltage output (1) with

permanently fitted ignition lead

1 2

217RA325 TG

:

Connector tag (2) for the short

circuit wire.

Testing in the workshop is limited to

a spark test. A new ignition module

with ignition lead must be installed if

no ignition spark is obtained (after

checking that the wiring and stop

switch are in good condition),

Ignition timing is fixed and cannot

be adjusted during repair work.

Since there is no mechanical wear

in these systems, ignition timing

cannot get out of adjustment during

operation.

:

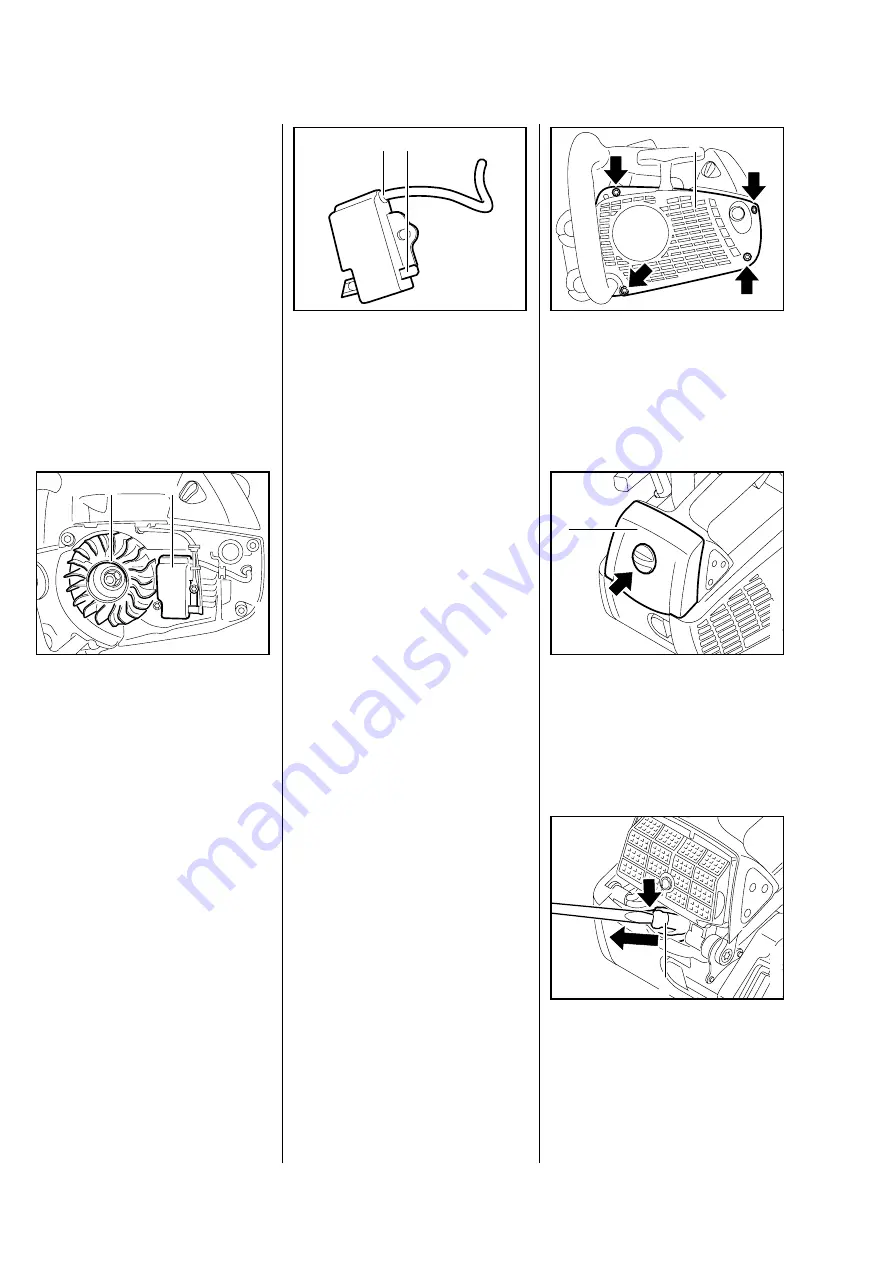

Take out the screws (arrows) and

remove the fan housing (1) with

rewind starter.

217RA087 TG

1

:

Turn the twist lock (arrow)

anticlockwise to release it and

remove the carburetor box

cover (1).

217RA008 TG

1

:

Apply a suitable tool to the tab

(arrow) to prise the boot off the

spark plug (1).

1

217RA009 TG

9.

Ignition System

9.1

Ignition Module

9.1.1

Removing and installing