page 16

When the fingerboard’s dry, remove the rubber band clamp.

The bone nut blank should be smooth-walled, square-bot-

tomed, and of uniform thickness. If it needs smoothing or

thicknessing, sand it with 100- and 220-grit sandpaper, dou-

ble-stick taped to a flat surface.

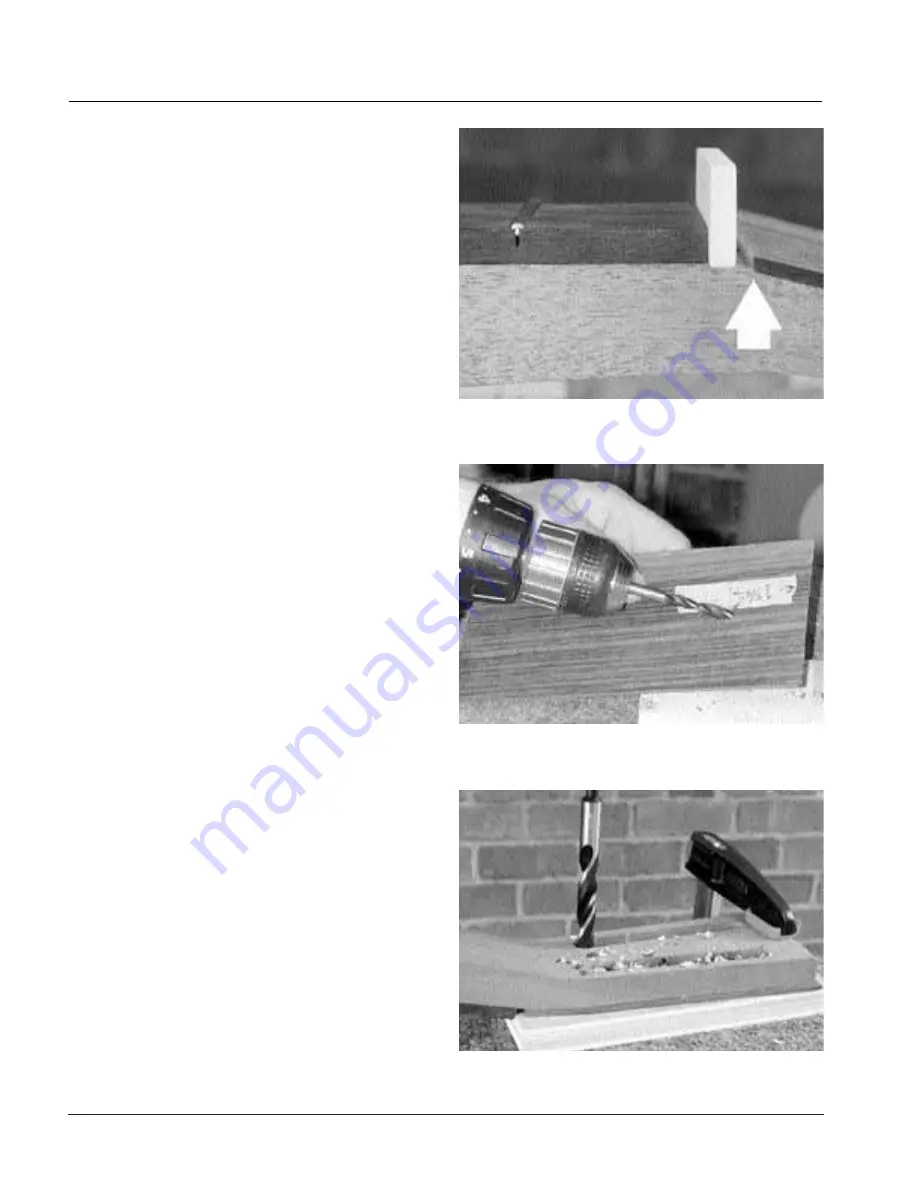

Place the nut blank on the flat ledge that remains between

the end of the fingerboard and the break angle of the peg-

head. File or sand a 14° angle on one end of the peghead

overlay so that it butts flush and tight up to the back edge of

the nut

(33)

. Once the overlay is glued on, the space

between the overlay and the fingerboard will be a perfectly-

sized channel for the nut.

Dry-clamp the overlay in place. With a pencil, mark a point 1-

9/16" from the back edge of the nut, centered on the

peghead’s width. Drill a 1/4" hole at that point. This is the

access hole for the truss rod.

Remove the clamps from the overlay. Hold the overlay in one

hand and elongate the hole by slowly tilting the overlay

against a running drill bit

(34)

. You may want to practice this

on a piece of scrap (there’s plenty of excess overlay that gets

trimmed away, so practice on that). You’ll end up with an

elongated access hole for the 1/8" Allen wrench that adjusts

the peghead.

Mark the peghead shape on the overlay. Trim away most of

the excess, to within 1/8" all around the peghead. Use pro-

tective cauls on the face and rear of the peghead, and glue

on the overlay. Keep the overlay pressed tightly against the

nut during alignment.

When the glue’s dry, clamp the peghead firmly, face down,

on a scrap of plywood. Use a 7/16" bit to drill holes against

each end of the tuning machine channels (the channel will

keep the drill bit lined up), and then drill several holes in

between these holes in the remainder of each channel

(35)

to eliminate as much of the wood as possible.

Installing the peghead overlay

33.

File or sand a 14° angle on one end of the overlay so that it fits

flush and tight to the nut.

34.

Hold the overlay in one hand and elongate the hole by slowly

tilting the overlay against the running drill bit.

35.

Use a 7/16" drill bit to drill holes against each end of the tuning

machine channels.