Digital Microstep Driver DM556N

10

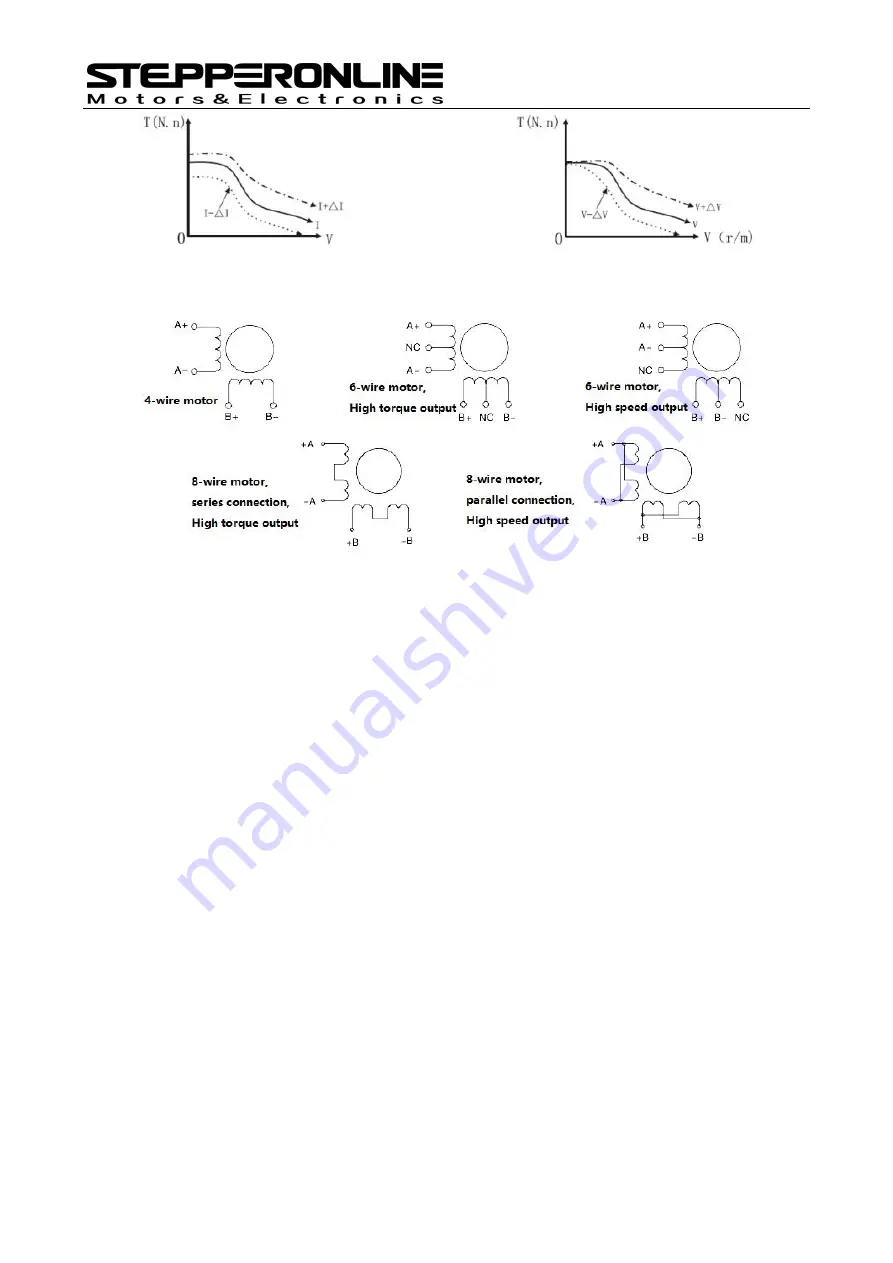

Figure 6: Torque frequency curve diagram

6.2 Motor connection

Figure 7: Motor connection diagram

6.3 Input voltage and output current selection

The DM556N driver can drive all two-phase and four-phase hybrid stepper motors. In order to

obtain the best driving effect, it is necessary to select a reasonable supply voltage and set current.

The voltage of the power determines the high-speed performance of the motor, and the current

determines the torque of the motor.

(1). Supply voltage setting

In general, the higher the supply voltage, the greater the torque at high-speeds, and the greater the

loss of speed at high speeds. On the other hand, if the voltage is too high, the motor will generate

more heat and may even damage the driver. At high voltages, the vibration of the motor at low

speeds will be greater.

(2). Output current setting

For the same motor, the larger the current setting value, the larger the motor output torque, but the

heat generated by the motor and the driver is more serious when the current is large. The calorific

value is not only related to the current setting value, but also to the motor motion form and the

motor dwell time. The following setting method uses the rated current value of the stepper motor

as a reference, but the optimum value in practical applications should be adjusted based on this

value. If the temperature is very low (<40

℃

), the current setting value can be increased to increase

the motor output power (torque and high-speed performance).

a. 4-wire motor and high-speed mode of 6-wire motor: output current is set equal to or slightly less

than the rated current of the motor;

b. High torque mode of 6-wire motor: output current is set to 70% of rated current;

c. Series connection of 8-wire motor: because the resistance increases in series, the output current

should be set to 70% of the rated current of the motor;