6918600000

13

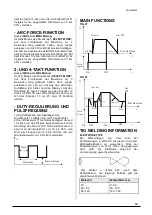

MAIN FUNCTIONS

TIG 2T

TIG 4T

TIG WELDING INFORMATION

ELECTRODE TYPE

STEL recommends the use of Ceriated Tungsten

electrodes (grey) for optimum arc ignition and

welding performance during either AC or DC

welding. A suitable electrode point is made as

shown in this example.

Angle a varies as the welding current varies; the

following table recommends the value:

FILLER MATERIAL

Basic rules:

1 ) Always use the same filler rod specification

with the same mechanical and chemical properties

as the material to be welded;

2) it is recommended not to use parts of the base

material, as they could contain impurities due to

the work process;

3) if the material used has a different chemical

composition, it is advisable to assess the final

characteristics of the joint, both mechanical and

anti-corrosive.

GAS

The shielding gas normally used is pure argon with

a gas flow rate that varies according to the current

used and joint set up (4-6 I/min).

TIG WELDING ON COPPER

Due to the properties already described, TIG

welding is also excellent for working on materials

with high heat conductivity. The gas used is mostly

argon and, in the case of copper, the use of a

reversed support is recommended. Preparation of

the edges for welding copper (flat butt joint).

The electrode used is of the same type described

for welding steel; it is prepared as described

above. To avoid possible oxidation in the welded

area, weld materials containing phosphor, silicon

and deoxidizing components are used.

Angle (°)

Welding current A

30

60 – 90

90 –120

5 - 30

30 - 120

120 - 160

On

Off

Arc on

Arc

off

Post Gas time

t

t

On

On

Arc on

Arc off

Post Gas time

t

t

Off

t

slope down

A

Torch

trigger

preGas

A

Torch

trigger

t

slope up

preGas

t

slope down

Off

Base Current 1

Base Current 2