Speedclean Eco 30

2011_V1

page 10 of 16

5.4

Power Source Instructions

The filter pump system you have purchase is equipped with a standard electrical cord and plug which should only

be connected to a power outlet protected by a qualified Ground –Fault-Circuit-Interrupter (GFCI) with I

Δ

N

≤

30mA

that has been installed by a professional electrician and adheres to local codes and regulations. Electrical installa-

tions should be carried out, taking the safety zone into consideration, by a locally licensed electrician to the rele-

vant national specifications for swimming pool construction (in Austria, EN1, part 4, §49; in Germany, DIN 57100,

Part 702 and VDE 0100, Part 702. To avoid electric shock, power cord extensions should not be used.

5.5

Setting up the filtration system

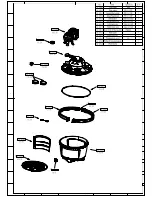

1. Filter Pump Assembly Instructions

a) The filter pump is screwed onto the cover of the filter system. Un-

screw the two screws (1) on the top of the cover:

b) Place the pump on the cover and secure it to the top of the cover

with the screws on both sides.

c) The front part of the pump should then be fastened (pointing vertical-

ly downwards) onto the cover at the pump nozzle, using the nut (2).

Ensure that the nut is properly tightened.

2. Filling the filter material

a) Release the screw on the clamp ring and remove the ring by lifting it upwards. Next raise the cover with

the O-ring (circumferential sealing cord). Once this has been completed, check to ensure that the bottom

strainer is correctly positioned and that the separation wall for the purified water chamber is seated

properly. In doing so, please note that the guide tracks on the bottom strainer grating are a continuation

of the side-mounted guide tracks on the container wall. The separation wall has to be slid onto these

tracks with by the side-mounted positioning hooks on its upper edge so that the upper edge of the wall

abuts with the upper container edge:

To prevent damage to the container and the bottom strainer, the container should be filled with 20 cm of water be-

fore adding the filter sand.

IMPORTANT

CAUTION

1

Intake from the

Sand Chamber

Filtered Water Chamber

Sand Chamber

Filter Bottom Strainer

Separation Wall between the

Filtered Water Chamber and

the Sand Chamber

Container drain below

the bottom strainer

2

Summary of Contents for Speedclean Eco 30

Page 17: ......