7.

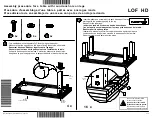

Turn new u-joint assembly upright and fill with Lubiplate or Amoco grease.

Make sure the new adjustable control arm is adjusted the same length as the

old one just removed.

NOTE: The adjustable control arm is adjusted so the

control button clears the front edge of outer seat shell 1/8” when front slide

control is adjusted in the down position.

Reverse the disassembly procedure

steps 6 thru 2 only and assemble the new parts.

NEW ADJUSTABLE

CONTROL ARM

Assembly Directions

93-9501164 REV B

Page

6 of 6

EXISTING DIMENSION FOR

OLD ADJUSTABLE CONTROL ARM

LUBRIPLATE OR

AMOCO GREASE

U-JOINT

ASSEMBLY

8.

Place the chair upright on the floor. Check the chair to verify that all functions are operating properly. Invert the

chair back onto workbench and reassemble the outer back shell onto upholstered back. This step is in reverse of

step 1, page 3 of these directions. You may wish to use an awl to find the existing screw holes on the inner back

assembly. Proper positioning is required for function appearance.

CONTROL

BUTTON

1/8”

FRONT

SLIDE

CONTROL