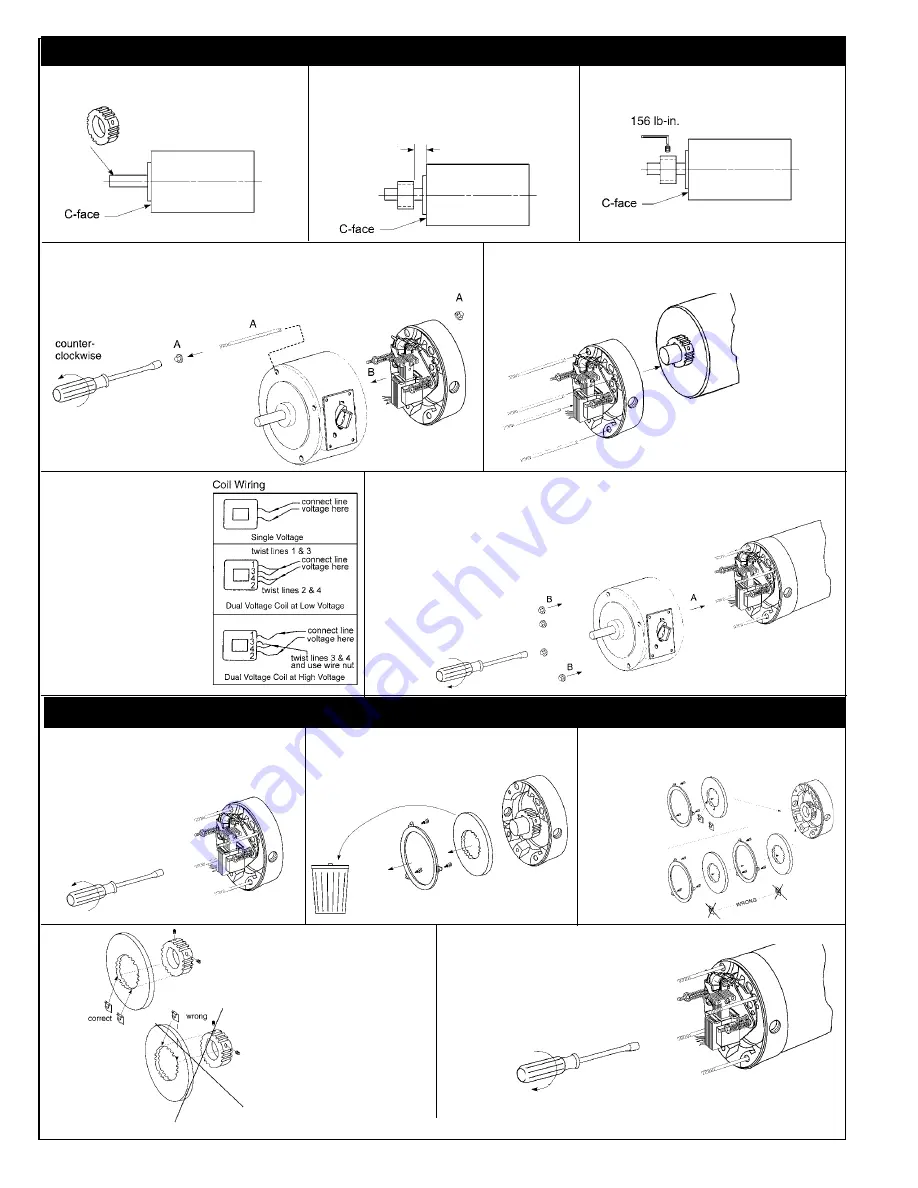

Position hub to X as shown:

X=.32” (8.1mm) for 1 & 2 disc (1.5 - 15 lb-ft)

X=.19” (4.8mm) for 3 disc (20 & 25 lb-ft)

Place hub on motor shaft.

Tighten set screws to motor shaft.

Connect coil lead-

wires to power

supply. Refer to

nameplate for volt-

age rating.*

Caution

:

Keep wiring away

from pinch points

and moving compo-

nents.

1

2

6

3

X

BRAKE MOUNTING (Manual Adjust) 1-056-700

* Stabilizer clips

are for use on

single disc units

only. Position

clips opposite

set screw holes.

Remove support plate screws and

lift support from brake

Reposition support plate on endplate and

tighten mounting screws to 55 lb-in.

Install new friction disc(s) and

stationary disc(s) as shown.

Remove and discard old friction disc.

4

2

1

3

clockwise

For brakes

with vertical

sprngs see

Figure 5A

or 5C.

FRICTION DISC REPLACEMENT SERIES 1-056-700

2

Note

: Friction discs can wear to 1/2 their original thicknes, or .093”

A. Remove housing nuts and slide tie bolt out of brake.

B. Remove housing from endplate.

4

* For vertical assembly

of 20 & 25 lb-ft brakes

refer to page 3.

Slide endplate over hub noting position of stabilizer clips, if

used. (Refer to Friction Disc Replacement view 3 and

3A). Mount

brake

endplate to

motor C-face

using the

four tie bolts.

Finger

tighten.

5

A. Slide housing and shaft assembly onto mounting studs, rotating

shaft until keyway is aligned. Be sure housing is assembled with

access windows in same position as shown in Figure 1, page 1.

B. Mount and secure brake/motor assembly to

C-face mounting register of reducer.

Using four 3/8 - 16 nuts and

lockwashers, tighten to 30-35 ft-lb.

clockwise

7

counter-clockwise

5