35

Various Adjustment and Inspections

Other Adjustments and Inspections

Tire Inspection:

1) Check for cracks, damage, foreign material on the tires, depth of tread lines in tires and tire wear, etc.

2) When tire(s) is functioning abnormally send it back to your dealer for inspection and repair/maintenance.

3) Check tire pressure to make sure it is normal.

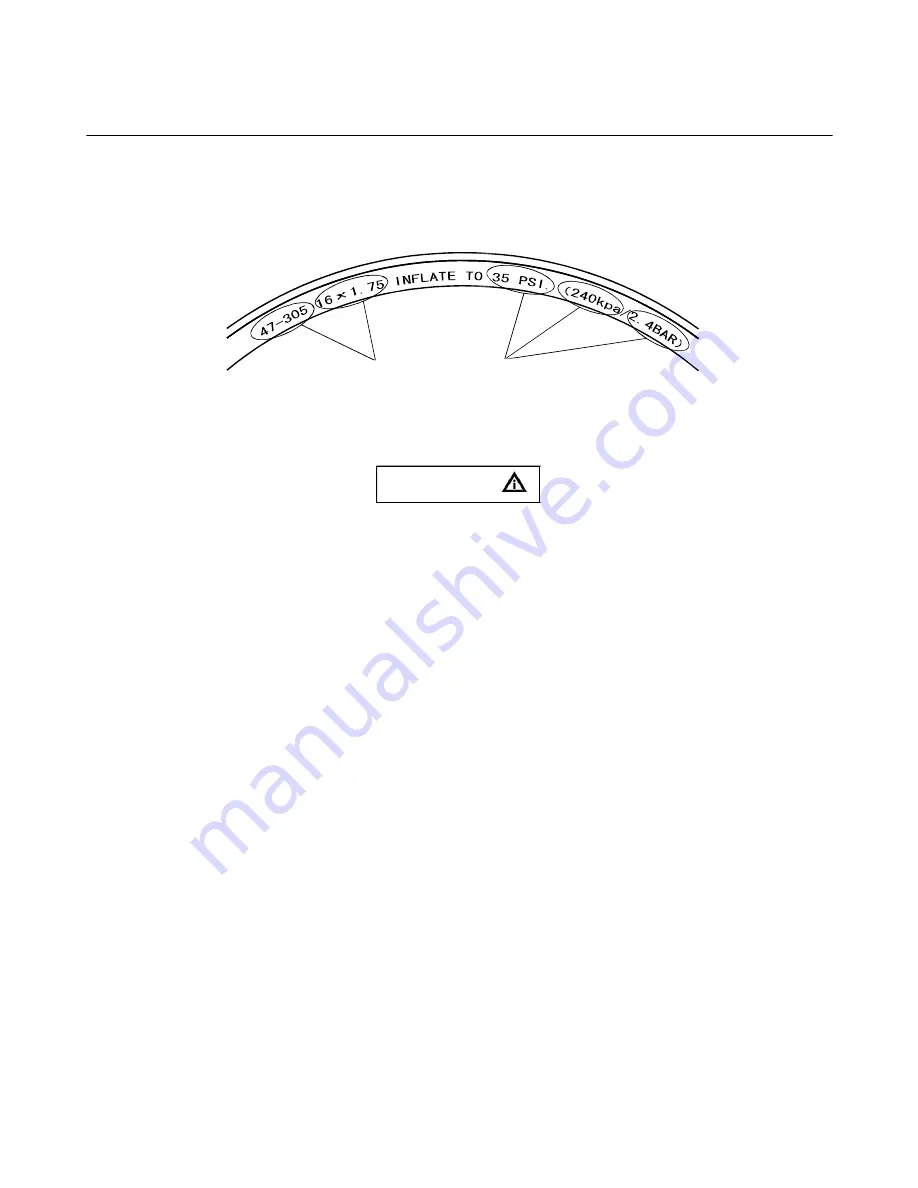

Tire size

Air pressure

Confirm if the air pressure is sufficient

– also is the air pressure the same as that of the recommended

imprints on the tire. (example above)

Fill the tire with air by following the recommended air pressure on the tire.

ATTENTION

Do not use leaking tires.

When there is a decrease in tire pressure, there is a risk of having a ruptured tire.

If tire pressure is too low, there is a risk that the tire will separate from the rim.

If the tire pressure is too high due to increased air pressure or heat, then there is a risk of the

tire rupturing.

Adjust both tires to the same air pressure.

Checking Around the Wheelchair:

1) If you think the wheelchair is working abnormally, then do a wheelchair check up

– adjustment, cleaning,

add oil, tighten bolts, etc.

2) If you think the axle is working unusually, ensure that an inspection is done, clean and oil the axle.

Other Items for Inspection:

1) Check over screws, bolts, and nuts once a month. Make sure these aren

’t loose, falling off, damaged,

or producing unusual sounds.

2) Check around the small wheels once a month. Make sure they are not bent, damaged, producing

unusual sounds, or have wheel rotation problems etc.

3) Every day check your brakes before riding. Check to see if they are responsive. Ensure that nuts, bolts

etc. are not loose and unable to fall off.

4) Every day before riding, ensure the armrest and handles are not wobbly or shaky, nuts and bolts

haven

’t loosened or producing any unusual sounds.

5) Inspect the chain if there are any abnormalities

– when necessary adjust, clean and oil the chain.