14

Battery Replacement

Replace the batteries immediately when it approaching to the battery life, as the capacity will

decrease quite fast and can’t meet the range requirement. The detailed replacement way can be

consulted with the supplier.

Remove battery hold downs and cables. Lift out batteries with a commercially available lifting

device.

If the batteries have been cleaned and any acid in the battery rack area neutralized as

recommended, no corrosion to the battery racks or surrounding area should be present. Any

corrosion found should be immediately removed with a putty knife and a wire brush. The area

should be washed with a solution of sodium bicarbonate (baking soda) and water and thoroughly

dried before priming and painting with a corrosion resistant paint.

The batteries should be placed into the battery racks and the battery hold downs tightened to 45 -

55 in. lbs. (5 - 6 Nm) torque, to prevent movement but not tight enough to cause distortion of the

battery cases.

Inspect all wires and terminals. Clean any corrosion from the battery terminals or the wire

terminals with a solution of sodium bicarbonate (baking soda) and brush clean.

WARNING:

To prevent battery explosion that could result in severe personal injury or

death, extreme care must be used with aerosol containers of battery terminal protectant.

Insulate the metal container to prevent the metal can from contacting battery terminals

which could result in an explosion.

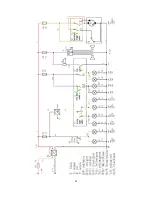

Use care to connect the battery wires as shown. Tighten the battery post hardware to 50 70 in. lbs.

(6 -8 Nm) torque. Protect the battery terminals and battery wire terminals with a commercially

available protective coating.

Battery Connections