9

Oil Flow

Hose Lengths

Inside Diameter

USE

(

Press/Return)

Min. W

orking Pressure

GPM

LPM

FEET

METERS

INCH

MM

PSI

BAR

Certi

fi

ed Non-Conductive Hose - Fiber Braid - for Utility Bucket T

rucks

4-9

15-34

up to 10

up to 3

3/8

10

Both

2250

155

Conductive Hose - W

ire Braid or Fiber Braid -DO NOT USE NEAR ELECTRICAL

CONDUCT

ORS

4-6

15-23

up to 25

up to 7.5

3/8

10

Both

2500

175

4-6

15-23

26-100

7.5-30

1/2

13

Both

2500

175

5-10.5

19-40

up to 50

up to 15

1/2

13

Both

2500

175

5-10.5

19-40

51-100

15-30

5/8

16

Both

2500

175

5-10.5

19-40

100-300

30-90

5/8

16

Pressure

2500

175

3/4

19

Return

2500

175

10-13

38-49

up to 50

up to 15

5/8

16

Both

2500

175

10-13

38-49

51-100

15-30

5/8

16

Pressure

2500

175

3/4

19

Return

2500

175

10-13

38-49

100-200

30-60

3/4

19

Pressure

2500

175

1

25.4

Return

2500

175

13-16

49-60

up to 25

up to 8

5/8

16

Pressure

2500

175

3/4

19

Return

2500

175

13-16

49-60

26-100

8-30

3/4

19

Pressure

2500

175

1

25.4

Return

2500

175

T

ypical Hose Connections

T

ool to Hydraulic Circuit Hose Recom-

mendations

The chart to the right shows recommended mini-

mum hose diameters for various hose lengths

based on gallons per minute (gpm)/liters per min-

ute (lpm).

These recommendations are intended

to keep return line pressure (back pressure) to a

minimum acceptable level to ensure maximum tool

performance.

This chart is intended to be used for hydraulic tool

applications only based on Stanley Hydraulic

T

ools

tool operating requirements and should not be used

for any other applications.

All hydraulic hose must have at least a rated

minimum working pressure equal to the maximum

hydraulic system relief valve setting.

All hydraulic hose must meet or exceed speci

fi -

cations as set forth by SAE J517.

PRESSURE

RETURN

<<< FLOW

FLOW >>>

Summary of Contents for DL07

Page 2: ......

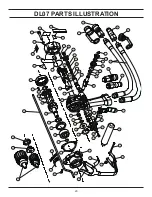

Page 20: ...20 DL07 PARTS ILLUSTRATION ...